Critical Performance Factors in Standing Seam Machines

High-Speed Operation for Commercial Efficiency

Speed matters a lot when it comes to getting more done while spending less on labor in construction work. Standing seam machines that run fast help boost project output substantially. Some research points to around a 30% improvement in how efficiently workers get their tasks done when machines operate quicker, which means jobs finish sooner than expected. Better tech has allowed manufacturers to build these machines with advanced hydraulics and stronger motors so they can go faster without sacrificing what gets produced. The end result? Companies save money because their equipment doesn't sit idle as much and they crank out more finished products overall.

Material Thickness Capacity (0.4-1.2mm Handling)

The ability of standing seam machines to work with different material thicknesses makes them really versatile across all sorts of roofing jobs. Most models today handle everything from 0.4mm up to 1.2mm sheets, something that's pretty important when it comes to making sure roofs hold up over time. The industry has set some guidelines about what thickness works best where too. Lighter gauge materials around 0.4-0.6mm are generally fine for homes while anything above 0.9mm tends to be better suited for bigger buildings like warehouses or shopping centers. Contractors who skip following these rules often end up dealing with problems down the road like roofs that sag under snow load or panels that just don't last as long as they should. Getting the right thickness right from the start isn't just about meeting code requirements either it actually saves money in maintenance costs later on for most roofing companies.

Precision Seaming with Advanced Control Systems

Getting those seams just right makes all the difference when it comes to roofs that stay dry and last for years. Modern standing seam machines come packed with smart controls that keep things accurate run after run. Most have computers inside along with sensors that tell them exactly where everything needs to go. Contractors who've used these systems report fewer leaks and better looking installations across the board. One roofing company saw their callbacks drop by half after switching to this tech. Beyond just looking good, these innovations actually stand up better against whatever Mother Nature throws at them. Rain, snow, extreme heat – nothing seems to phase them over time.

Durability and Adaptability Requirements

Industrial-Grade Construction Materials

The durability of standing seam machines really comes down to what kind of materials go into building them. Industrial grade components make all the difference when it comes to handling day after day of tough work, which naturally makes these machines last much longer. According to field reports, good quality steel or aluminum builds typically see service lives well past two decades in most shop environments. Steel remains popular because nobody wants parts breaking down under stress, plus it stands up to wear and tear pretty well. Aluminum has gained traction too since it's lighter weight makes maintenance easier without sacrificing protection against rust issues. When spec'ing out equipment, getting the material selection right means the difference between machines that hold up through rough conditions and ones that start showing signs of fatigue way too soon.

Weather-Resistant Component Design

Standing seam machines last much longer when built with weather resistance in mind. The addition of things like coatings that resist corrosion really makes a difference in protecting equipment from wear and tear due to environmental factors. Design improvements often involve applying rust proofing treatments and adding layers against moisture, which becomes absolutely critical where there's lots of humidity or salty air around. Some research actually points to about a third longer life span for machines operating in those tough conditions. Looking at it practically, these aren't just nice to have additions anymore. They're pretty much required if manufacturers want their machines to keep working reliably across all sorts of different climates without constant breakdowns.

Multi-Metal Compatibility (Steel/Aluminum)

Standing seam machines that work with various metals open up new markets for manufacturers. Machines fixed to handle both steel and aluminum meet diverse demands across construction projects big and small. According to recent market reports, steel remains popular for commercial buildings while aluminum is gaining traction in residential applications because it lasts longer and looks better over time. To make all this possible, technicians modify equipment with special rollers designed specifically for each metal type. These adjustments let the machinery process harder or softer materials efficiently without compromising quality. The result? A single machine becomes useful for many different jobs on site, which explains why contractors increasingly specify multi-metal capable models when bidding on contracts.

Leading Standing Seam Machines Comparison

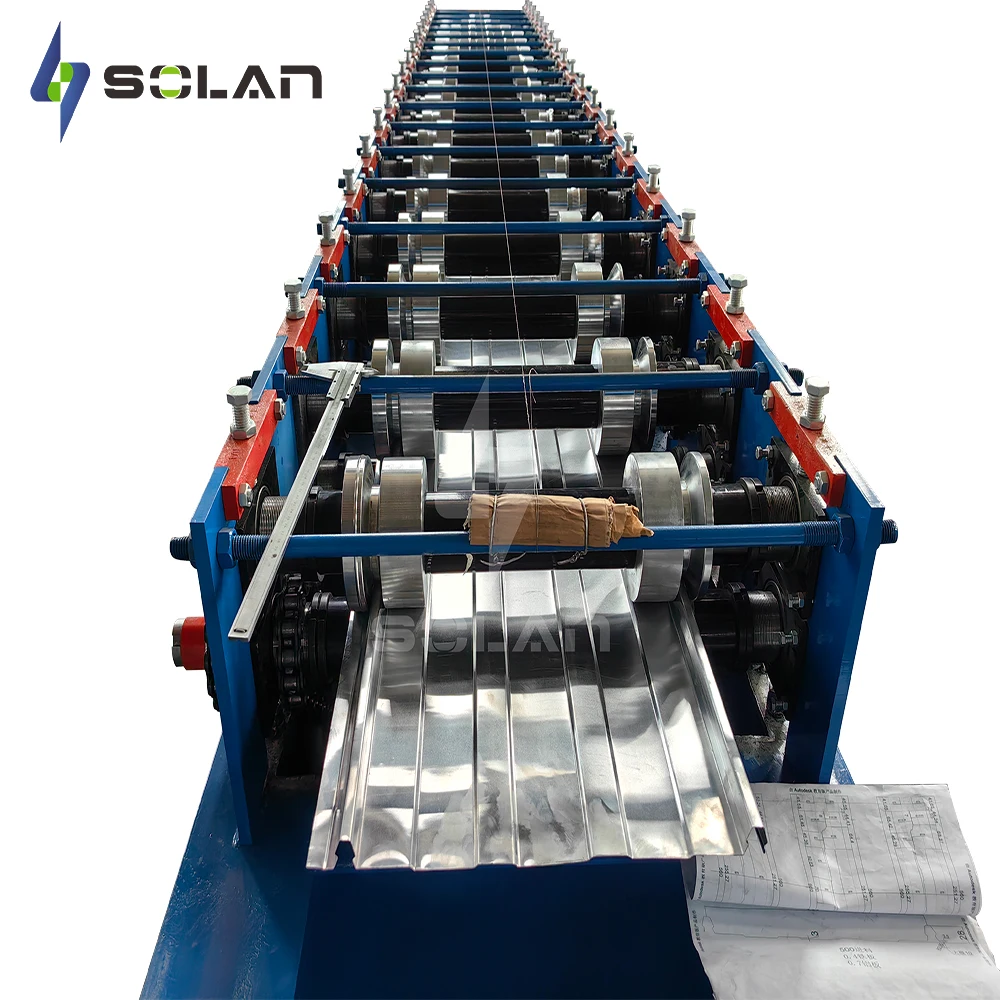

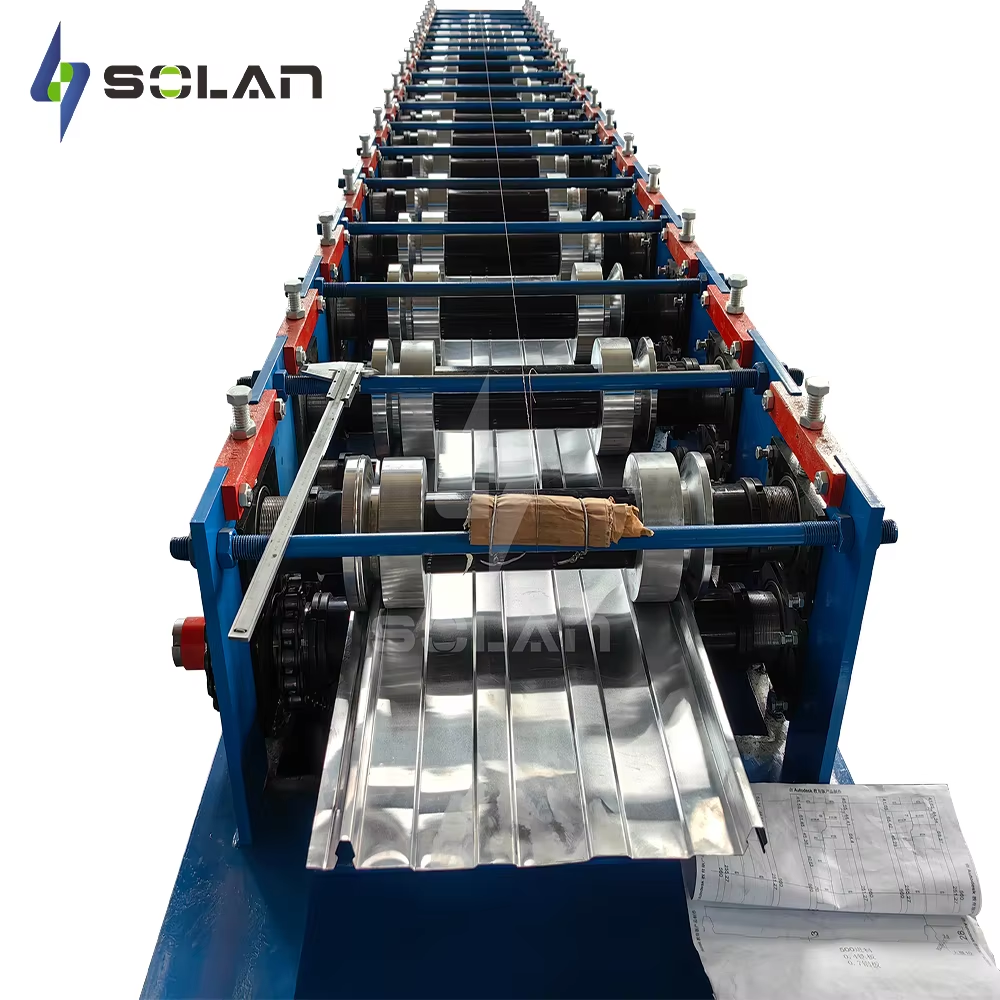

Construction Aluminum Roof Standing Seam Roll Forming Machine

What really sets the Construction Aluminum Roof Standing Seam Roll Forming Machine apart is how precisely it forms those metal sheets while maintaining incredible efficiency throughout production runs. The system combines high precision molds with sophisticated computer controls so every single panel comes out exactly right for whatever building specs are needed. Built using heavy duty steel components that resist wear over time, these machines keep performing reliably year after year even under tough conditions. Contractors love this equipment because they can easily adjust settings to produce different panel profiles according to project requirements. Some shops run standard configurations most days but switch things up when clients request special designs or dimensions. That kind of adaptability makes all the difference when working on diverse construction sites where one size definitely doesn't fit all.

The market position of this machine is highly favorable, earning positive user reviews for its efficient production capabilities and customization options. Contractors frequently highlight the machine's ability to reduce production costs while maintaining high panel accuracy.

For those interested in exploring this machine, the pricing details are readily accessible, ensuring potential buyers can make informed purchasing decisions. Learn more about the Construction Aluminum Roof Standing Seam Roll Forming Machine.

2025 Snap Lock Standing Seam Roofing Sheet Machine

The new 2025 Snap Lock Standing Seam Roofing Sheet Machine brings something special to the table with its advanced tech features that most competitors just don't have. What really stands out is the Quick-Snap Technology built right into the system, which cuts down on panel joining time by around 40% compared to older models. Contractors working against tight deadlines will appreciate this when installing large roof sections. Another big plus is the dual speed function that can crank out sheets at up to 35 meters per minute. This means getting more done in less time during those busy installation periods. Plus, the whole unit isn't some massive beast to transport either. Its compact size makes moving between job sites much easier without sacrificing any of the performance benefits that make this machine so attractive to professionals looking to boost their workflow efficiency.

This machine targets various sectors, including commercial roofing, architectural metal projects, and industrial facilities, each benefiting from the machine's unique capabilities. The energy-efficient design further boosts its relevance, offering 30% power savings through an auto-idle mode, which appeals to environmentally conscious purchasers.

Feedback from users highlights its ease of use and reliability, with performance benchmarks affirming its effectiveness across diverse applications. As a true leader in standing seam production technology, this machine represents a significant step forward for professionals.

Explore the features of the 2025 Snap Lock Standing Seam Roofing Sheet Machine.

Smart Investment Considerations

Energy-Efficient Operation Features

Getting hold of energy efficient standing seam machines pays off in the long run with significantly lower running costs. Good quality models come equipped with various features designed to cut down on power use, including newer motor tech and smart power management options. All these little improvements add up to real money saved on monthly electricity bills while making the business more profitable overall. Research shows companies using efficient machinery tend to see around a 15% boost in profits, numbers backed up by reports from energy efficiency programs across different industries. And let's not forget about those government incentives either. Tax breaks and rebate programs for green equipment can really bring down initial purchase costs. What makes this even better is that these financial benefits go hand in hand with greener operations, creating a win-win situation where businesses save money and help protect the environment at the same time.

Custom Profile Configuration Options

The ability to configure profiles on standing seam machines is really important when trying to satisfy all sorts of customer requests while keeping products versatile enough for multiple uses. Modern engineering has made it possible for these machines to create special profiles suited for particular jobs, something that matters a lot in fields like building construction and architectural work where certain profile types are needed regularly. Both home roof installations and big commercial buildings get real value from this customization feature since it lets them meet exact measurements and look good at the same time. For anyone working on creating those custom profiles, there are several things worth thinking about first. Machine flexibility comes to mind right away, along with what materials will actually work together properly. Sometimes small tweaks or new ideas can make a big difference in how well everything fits together on metal roofs. Having this kind of adaptability means the machines stay useful no matter what type of job comes along next, matching up exactly with whatever specific needs each project might have.

Warranty and Technical Support Networks

When someone invests in standing seam machines, having good warranty coverage really matters for building trust. Most decent warranties will take care of replacement parts and labor costs, and some actually include routine maintenance checks too. This kind of protection helps keep the machines running well over time. Warranties generally last anywhere between 1 year up to several years depending on what exactly they cover regarding repairs and maintenance needs. Technical support availability makes all the difference too. When manufacturers have reliable tech teams on standby, operators can get their problems sorted out faster and keep productivity levels high. For businesses dealing with complicated equipment setups, this kind of backup becomes absolutely essential. Buyers tend to look closely at both warranty conditions and how accessible technical assistance is before making a purchase decision. These factors end up shaping perceptions about brand reliability and overall customer happiness in the long run.