The Role of Standing Seam Machines in Construction Efficiency

How Automated Metal Roof Making Boosts Productivity

Metal roof manufacturing machines have revolutionized how fast construction projects get done. These automated systems cut down on mistakes made during manual processes while making everything run smoother from start to finish. What's really impressive is how they crank out roof panels at lightning speed compared to traditional methods. For big commercial jobs where time matters most, being able to produce hundreds of panels an hour makes all the difference when facing those impossible deadlines. Plus, since workers aren't spending hours bending metal by hand anymore, crews can focus their efforts on tricky installation work that actually requires skilled hands. The result? Fewer defects in the finished product because every panel comes off the machine within strict tolerances. Contractors who've switched to these systems report noticeable improvements in both project timelines and customer satisfaction rates.

Reducing Labor Costs with Precision Machinery

Standing seam machines are just one example where precision equipment really cuts down on labor expenses. When these machines operate properly, they cut down on wasted materials during production runs. Less scrap means lower costs for buying raw materials. The automation aspect makes a big difference too. Metal roofing panels get produced at consistent speeds without needing constant supervision from workers. Some industry reports indicate that going fully automated can slash labor bills by around 30 percent. That kind of savings adds up over time for any business owner watching their bottom line. Plus, when everything runs smoothly through precision machinery, the end product maintains quality standards that customers expect. Panels last longer this way, so the investment pays off in the long run.

For more information, check out this link: [Standing Seam Metal Roof Machine](#).

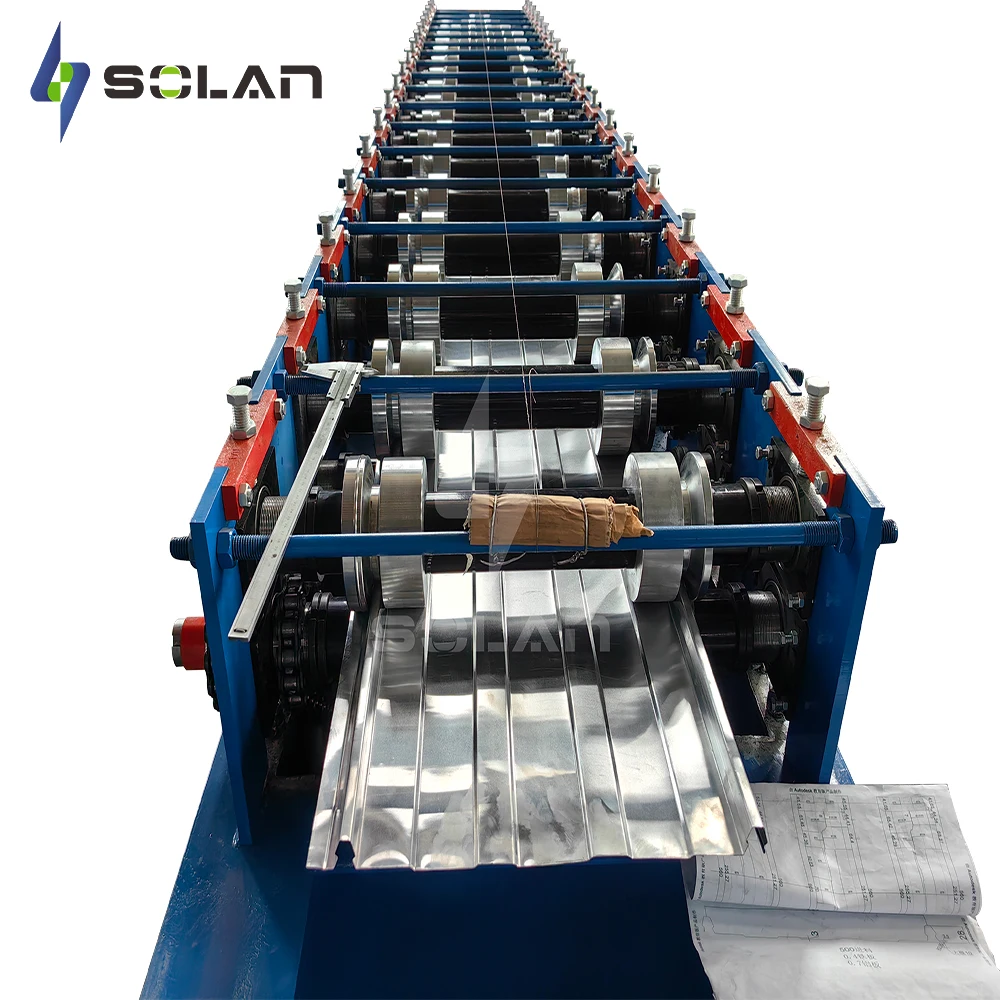

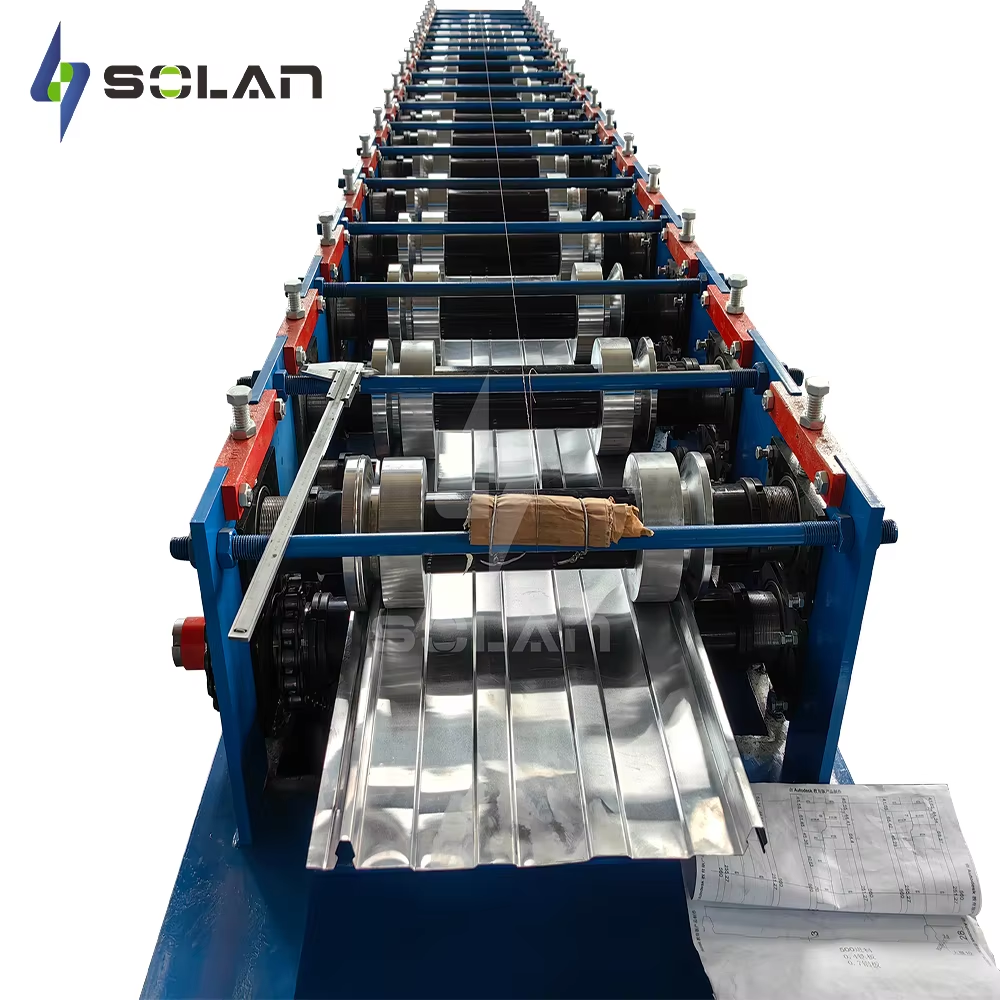

Key Features of High-Efficiency Standing Seam Machines

Advanced Control Systems for Consistent Output

Standing seam machines with high efficiency come with control systems that really matter when it comes to keeping output quality consistent across all panels. The newer models have incorporated some pretty good tech these days so every single roofing panel hits those specs right on target. One thing that stands out about them is their real time monitoring ability. When something goes off track during manufacturing, operators spot it fast and fix whatever issue arises before it becomes a bigger problem. That makes the whole system much more reliable in day to day operations. Another benefit worth mentioning is how these control systems let manufacturers program settings ahead of time for different job sites. Setup takes less time overall while still getting those precise results everyone wants. Contractors who invest in this kind of equipment generally find themselves producing panels that look uniform and meet quality standards consistently throughout large scale installations.

Dual-Speed Operations for Versatile Applications

Standing seam machines with dual speed settings give contractors real flexibility when tackling different jobs. Contractors can switch back and forth between fast production speeds needed for big orders and slower settings that let them focus on details for specialty work. This kind of adaptability means the same machine works well with all sorts of materials across many project types from simple home repairs right up to major commercial developments. For anyone in the field looking for equipment that keeps pace with changing job site demands, dual speed capability isn't just nice to have it's practically essential for getting through day to day challenges without constantly swapping out tools.

Top Standing Seam Machines for Enhanced Productivity

Construction Aluminum Roof Standing Seam Roll Forming Machine: Precision & Customization

When it comes to roofing, the aluminum roof standing seam roll forming machine really stands out from the competition. What makes this equipment so special? It creates custom profiles that fit exactly what each project needs, which means stronger roofs overall and less wasted materials on site. Contractors love how fast they can produce quality panels with minimal setup time between jobs. For commercial builders working against clock ticking deadlines, especially those dealing with large warehouse installations or industrial buildings, this machine just works better than anything else available right now. The speed combined with accuracy saves both time and money across multiple construction sites throughout the year.

2025 Quick-Snap Roofing Machine: Portability & Energy Savings

The new 2025 Quick Snap Roofing Machine brings something special to the table with its compact design and impressive power efficiency, which makes it a real asset for roofers working at different sites. Contractors love how easy it is to move from one location to another without dealing with cumbersome equipment transfers. The machine's green tech actually cuts down on fuel costs significantly over long projects, something that matters a lot when budgets are tight. Real world testing shows workers can get up and running faster than ever before, cutting setup times in half according to several roofing crews who've tried it out. This translates into real money saved for businesses since they finish installations quicker and take on more projects each month.

Applications Driving Modern Construction Efficiency

Commercial Roofing Projects: Speed and Durability

Commercial buildings are increasingly turning to standing seam roofing systems thanks to how fast they install compared to traditional methods. The way these panels lock together makes setup much simpler for crews, cutting down on labor hours and getting projects wrapped up sooner. What really sells this system though is durability factor. Roofs built with standing seams often stick around for half a century or more before needing major work, which means fewer headaches down the road. We're seeing a clear shift in the market toward metal options for commercial properties lately. Contractors love them not just because they hold up against harsh weather but also because they save money over time. Metal's strength against storms and extreme temperatures keeps making sense for anyone looking to build smarter while staying within budget constraints.

Solar-Ready Designs for Sustainable Building

Standing seam machines today come with features specifically designed for solar panel installation, helping push sustainability forward in construction circles. The latest models make it much easier to incorporate solar tech right into roof systems without compromising structural integrity, which means buildings can generate their own power while still looking good. Property owners have noticed something interesting too buildings with solar ready roofs tend to sell for better prices and save money on electricity bills month after month because they actually produce some of their own energy. Real estate developers who invest in these kinds of machines gain advantages both environmentally and financially as demand grows for eco friendly homes. We're seeing a shift toward green building methods across the board, and having roofs that work well with solar panels is definitely part of what's driving this trend right now.

Maintenance Best Practices for Optimal Performance

Daily Inspection Routines to Prevent Downtime

Checking standing seam machines regularly throughout the day helps keep them running smoothly. A quick look at components showing signs of wear makes all the difference in keeping operations efficient. When businesses stick to proper maintenance routines, they catch small problems early before they turn into big headaches later. Plus, well-maintained equipment means fewer unexpected shutdowns that disrupt production schedules. According to industry data, manufacturers who prioritize preventive care tend to see their machines last around 30% longer than those who neglect routine upkeep. That translates to real money saved when replacements aren't needed as frequently.

Lubrication Strategies for Long-Term Reliability

Getting the lubrication right makes all the difference when it comes to keeping standing seam roofing machines running for years. Good lubrication cuts down on friction so parts don't overheat, something that really matters if we want these expensive tools lasting through their full service life. Most maintenance manuals suggest sticking to regular lubrication intervals, maybe every few months depending on usage levels. Industry pros tend to point towards certain grease types that work better under different weather conditions, especially in places where temperature swings are common. Machines just perform better when properly greased, no matter what kind of job site they're on. We've seen firsthand how neglecting this basic step leads to breakdowns during critical installation periods.