The Role of Precision Purlin Systems in Earthquake-Resistant Design

Why Steel Framing Matters in Seismic Zones

When building in areas where earthquakes are common, steel framing becomes really important because of how flexible and strong it actually is. Steel can take in all that shaking energy when the ground moves around. According to the folks at AISC, buildings made with steel frames can handle way more weight than other options, which is why they work so well in places that get hit by quakes regularly. What makes this possible? Well, steel just has certain properties that let it spread out the force across different parts of the structure during an earthquake. We've seen this happen time and again in various tests comparing different building materials. Structures built with steel frames tend to come out of earthquakes with far less damage compared to wooden buildings or other traditional materials. That's why many architects and engineers prefer steel framing these days—it doesn't just look good on paper, it literally saves lives and protects valuable assets when disaster strikes.

How Purlin Systems Absorb Seismic Forces

Purlin systems serve as critical support structures in buildings designed to resist earthquakes. They work by spreading out and taking in the shock waves from tremors, which helps prevent total collapse of the structure. When earthquakes strike, these systems keep buildings standing despite all the shaking and movement. Well-designed purlins include backup elements so they continue working properly even if parts get damaged somehow. Studies indicate that structures with carefully crafted purlin systems handle side-to-side forces better during quakes than those without them. For areas that experience frequent earthquakes, having reliable purlin systems makes a huge difference. Buildings can survive smaller shakes and stand firm through bigger ones too, saving lives and reducing repair costs after disasters hit.

Advantages Over Traditional Wooden Supports

Switching from wood to steel purlins in construction makes sense for many reasons. Steel stands up better against things like water damage and insects, so buildings last longer without needing constant repairs. As lumber gets pricier these days and forests get cut down faster than they regrow, going with steel purlin roll forming systems starts looking pretty smart economically speaking. According to figures from the National Council of Structural Engineers Associations, buildings made with steel instead of wood in areas prone to earthquakes actually hold together about 30 percent better during tremors. That kind of number really highlights why steel is gaining ground as both an environmentally friendly option and one that saves money long term while making structures safer where quakes are a concern.

Essential Features of Modern Purlin Roll Forming Systems

Precision Engineering for Structural Integrity

Purlin roll forming systems have come a long way thanks to better engineering that keeps structures strong and stable. These days most systems use CNC machines which cut parts with incredible accuracy. This matters because it doesn't just meet old school quality standards anymore it actually beats them hands down. During production, companies run all sorts of tests on vibrations and stresses to see how well materials hold up. Think about buildings standing through storms or extreme heat those tests give real world data about durability. Getting ISO certified isn't just paperwork either. For manufacturers wanting their products accepted worldwide, this stamp of approval means customers know what they're buying meets global quality expectations every single time.

Material Versatility: Galvanized Steel to High-Strength Alloys

Material options have become one of the biggest selling points in today's purlin manufacturing landscape. We see everything from standard galvanized steel all the way up to specialty high strength alloys hitting the market. Galvanized steel remains popular because it fights off rust so well, which means these purlins last much longer when exposed to harsh weather conditions something architects really care about when designing buildings in seismic zones. The newer high strength alloys are changing things too they allow engineers to create much thinner structural components while still maintaining required strength levels. This matters a lot for projects where every extra pound counts against building codes or transportation costs. As construction specs continue evolving, having multiple material choices available helps meet those ever-changing demands for both safety standards and innovative design solutions.

Seismic-Grade Component Manufacturing

Manufacturing components for seismic applications requires thorough testing to meet standards such as ASCE 7. The detailed work during production actually makes these parts perform better when put through earthquake simulations, giving engineers peace of mind when they specify them for buildings. Getting approval from groups like ICC-ES or IAPMO basically proves that these materials will stand up to real shaking events, especially important for structures located near fault lines. Beyond just meeting codes, this kind of certification shows the construction sector cares about people's safety first, not just cutting corners on costs. When buildings can withstand tremors without failing, communities become safer places to live and work.

Spotlight: High-Quality C Channel Purlin Roll Forming Machine

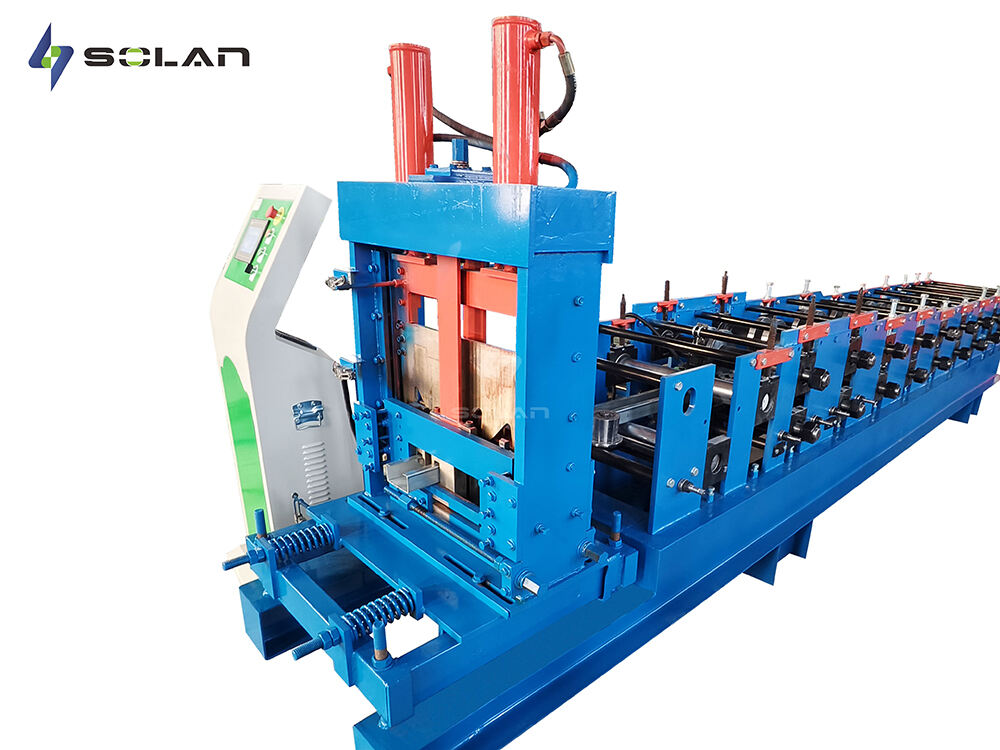

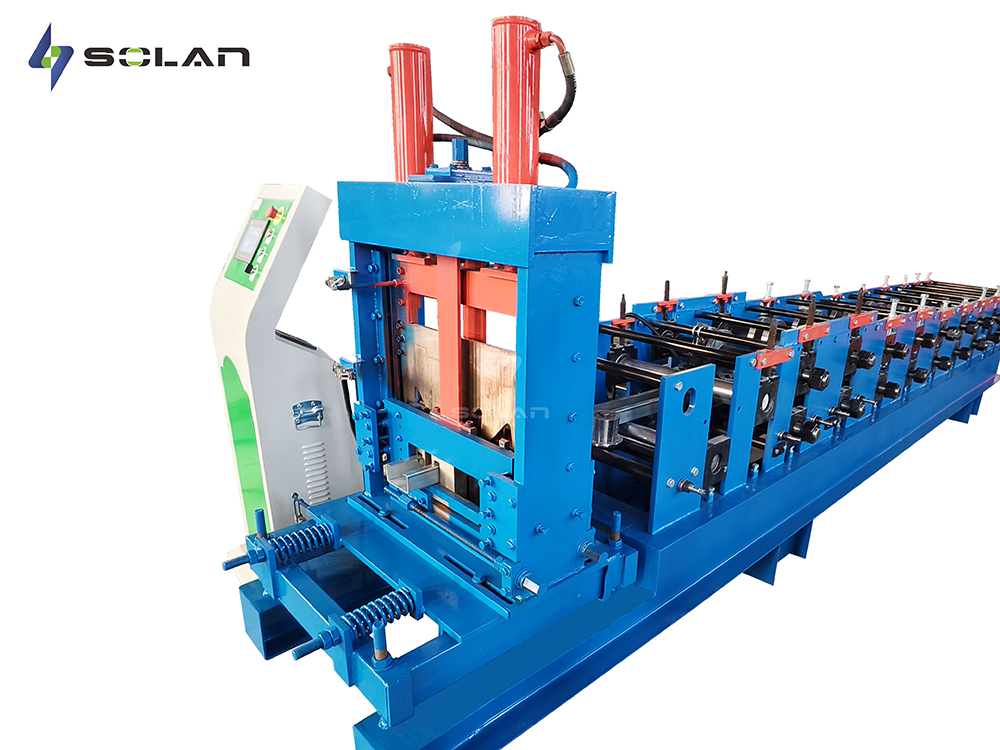

Industrial-Grade Construction for Seismic Demands

C channel purlin roll forming machines are built using durable steel alloys designed to withstand long hours of operation and satisfy earthquake resistance requirements. These machines need to keep going through tough production runs day after day, which makes them essential in factories across various industries, especially where buildings must resist tremors. After construction, each machine goes through extensive stress tests to confirm it produces consistent quality parts even when faced with unexpected challenges during operation. Manufacturers stick closely to established guidelines not just because regulations demand it, but because real world experience shows that equipment capable of producing strong, reliable components matters most in areas where building codes require extra protection against ground shaking events.

Multi-Function Capacity: Purlins & Roofing Sheets

What really sets the C channel purlin roll forming machine apart is how it handles multiple functions at once, making it possible to produce both purlins and roofing sheets without breaking a sweat. The real advantage here goes beyond just saving time on the shop floor. When manufacturers need to pivot from one design to another, these machines come equipped with tooling systems that let them make those switches pretty much instantly. This kind of adaptability means construction companies can tackle all sorts of projects without having to wait weeks for equipment changes. Some shops report cutting their production costs down around 20% simply because they spend less time waiting for machines to be reconfigured and get back up to speed after each job change.

Technical Superiority in Earthquake Scenarios

The newest generation of purlin roll forming machines comes packed with tech upgrades that really make them stand out when dealing with earthquakes. These improvements let manufacturers create parts that hold up much better during tremors and other extreme shaking situations. Looking at real world tests after major quakes shows just how much better these modern machines perform compared to older models. Construction professionals keep pointing out that using quality roll forming equipment results in finished structures that actually meet and sometimes even beat what building codes require for seismic resistance. Builders can sleep easier knowing their projects will withstand unexpected ground movements thanks to these advances in manufacturing technology.

Implementing Roll-Formed Purlins in Seismic Zones

Integration with Standing Seam Metal Roof Systems

Roll formed purlins work really well when combined with standing seam metal roofs, creating a structural system that stands up better against earthquakes. When these components come together, buildings become more stable during tremors while looking nicer on the outside too. Plus, there's improved insulation performance which helps control indoor temperatures. Recent research shows buildings with these purlin systems tend to fail much less often during earthquake tests compared to other options. For anyone designing buildings in earthquake-prone areas, going with roll formed purlins makes sense from both safety and durability standpoints. Most professionals who've used them report fewer problems over time, especially after major seismic activity.

Case Studies: Earthquake-Resistant Warehouses

Looking at actual warehouse case studies where roll formed purlins were installed shows明显 fewer damages and better safety scores after earthquakes hit. Numbers back this up too when comparing building strength before and after quakes strike, which makes it pretty obvious why purlin systems matter so much in real buildings. Working alongside structural engineers on these projects also reveals some good practices, especially around how these particular purlins boost resistance during shakes and tremors. For anyone involved in construction, studying what happened in these warehouses offers concrete lessons about building smarter structures in areas prone to earthquakes.

Compliance with Global Seismic Standards

Roll formed purlins work really well with international seismic codes so buildings made with them generally pass all the required safety checks. Looking at what's happening around the world with seismic regulations shows why more builders are turning to steel these days. Steel just makes sense because it's strong enough to handle stress and can bend without breaking when needed. The fact that major regulatory agencies have given their approval adds weight to this approach. These organizations actually consult with earthquake specialists who test different materials under simulated conditions. So when contractors choose roll formed purlins for their projects, they're not just ticking boxes on paperwork requirements. They're helping create structures that stand up better during earthquakes, especially important in areas where tremors happen frequently.