Core Functionality in Steel Framing Systems

Structural Role of Purlins in Metal Roofing

Purlins form a key part of metal roof structures, supporting weight distribution across the entire system. These metal beams connect the roof panels to the main building framework, essentially bridging the gap between different structural elements. Without proper purlin installation, metal roofs would struggle against harsh weather conditions like strong winds or heavy snow loads, which could lead to premature failure. Metal roofing contractors know from experience that when purlins are correctly spaced and installed according to manufacturer specs, the whole roof lasts much longer because the stress gets distributed evenly instead of concentrating on individual panels. For this reason, most contemporary metal roof designs include purlins as standard components, even though some budget-minded builders might try to skip them to save costs upfront.

Integration with Metal Roof Making Machinery

When manufacturers integrate purlins into advanced metal roof fabrication equipment, they see a significant boost in production flow and general efficiency across the shop floor. Automated purlin manufacturing cuts down on mistakes made during manual assembly while ensuring each piece meets consistent quality standards. Real world data shows that companies adopting this technology often cut their production cycles by around 30 percent, something that matters a lot as demand for metal roofing keeps rising steadily. Shops that invest in these kinds of systems typically find their workflow becomes smoother day after day, which translates directly into higher output numbers without compromising on product quality. This kind of machinery isn't just another gadget it represents genuine progress in construction materials manufacturing, helping shops keep pace with competitors who are also upgrading their facilities.

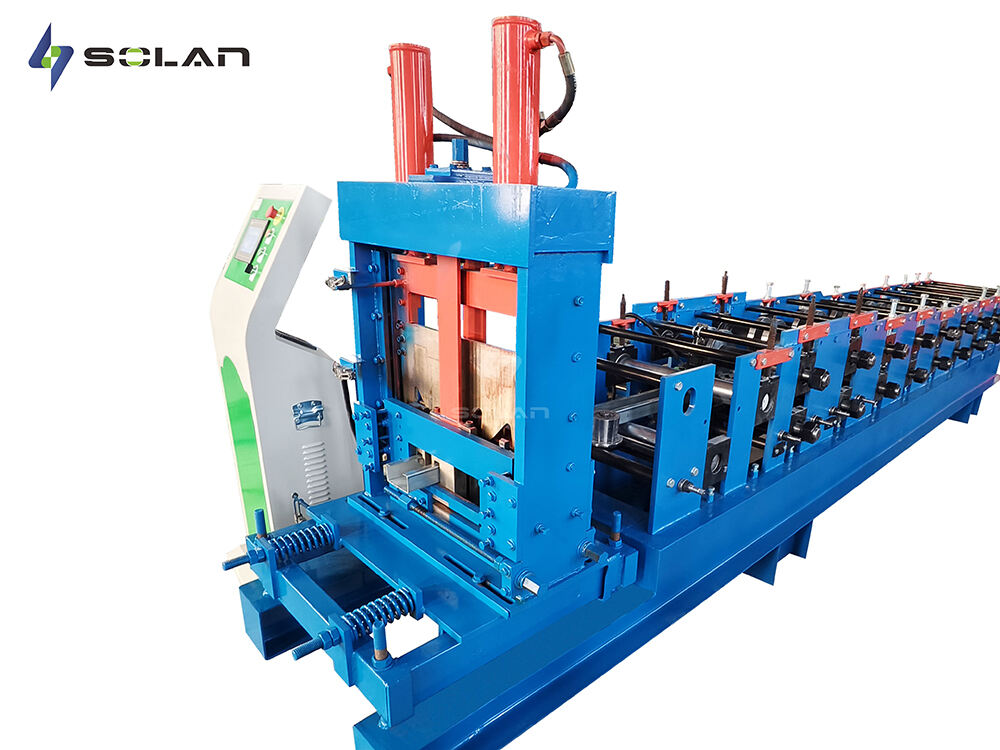

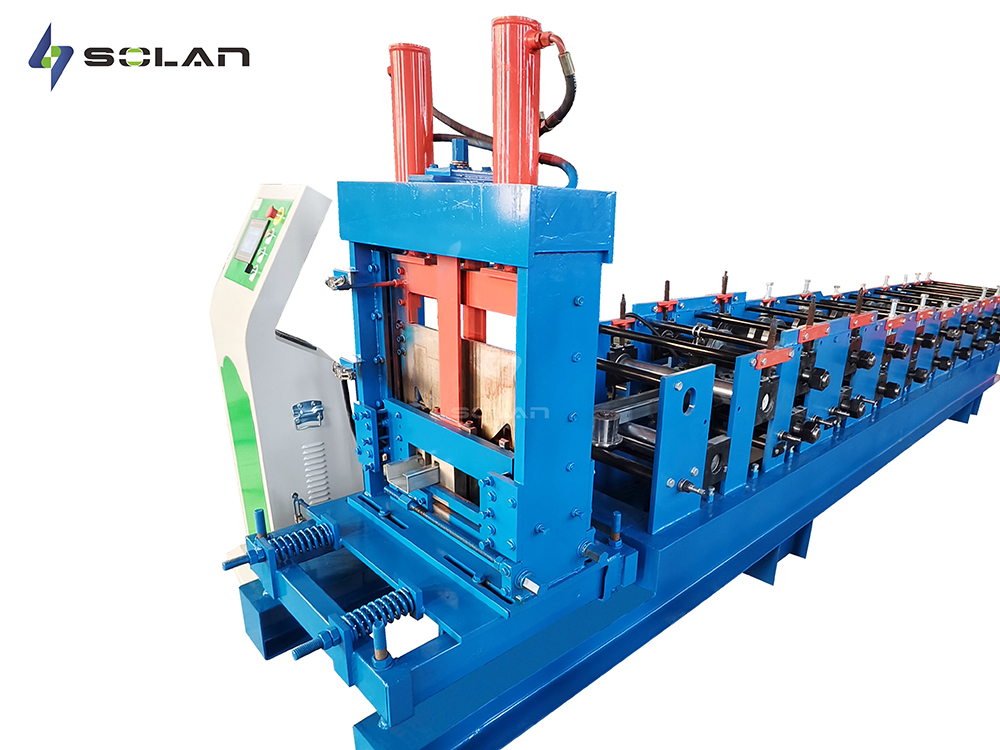

High-Quality C Channel Purlin Machine: Engineering Excellence

Precision Roll Forming Capabilities (±0.2mm Tolerance)

Getting the measurements right during roll forming makes all the difference for quality purlin production. When manufacturers stick to a tolerance range around 0.2mm as per standard specs, the parts actually fit together better, which strengthens how the whole structure holds up in practice. The tighter control means buildings last longer without issues and there's less scrap material going to waste. Some studies have shown that shops using precision machinery cut down on mistakes during manufacturing runs, and this saves money month after month even if it takes a bit more upfront investment in good equipment.

Multi-Function Design for Roofing Sheet Compatibility

C Channel purlin machines come with multiple functions built right in, making them really versatile when it comes to creating all sorts of roofing profiles that match what different customers need. What makes these machines stand out is their ability to work with various roofing materials without much hassle, something that boosts both flexibility on the factory floor and overall production speed. As construction demands keep changing from one project to another, manufacturers are finding that multi-functional equipment isn't just helpful anymore but almost essential for staying competitive. This kind of machinery helps streamline operations while getting roofs made faster than ever before.

High-Speed Production at 30m/min

The ability to produce at speeds reaching 30 meters per minute gives manufacturers a real edge when they need to respond quickly to what the market wants. Faster production means simply more stuff gets made in less time. Companies can handle big orders without breaking a sweat, and still keep product quality where it should be. Looking at the numbers from various industry studies, factories that upgrade to these high speed systems often see their productivity jump around 40%. For anyone selling metal roof machines or working in similar manufacturing sectors, this kind of speed difference matters a lot in staying competitive these days.

Technical Components Powering Operational Efficiency

German-Engineered Gear Reduction System

When it comes to getting the most out of purlin roll forming machines, integrating those German-made gear reduction systems makes all the difference. These bad boys have built a reputation for being rock solid reliable, cutting down on mechanical strain while giving operators a nice boost in torque when needed. What really stands out about these German gears is how they slash energy usage throughout the production process. Industry folks know that machines equipped with these advanced systems tend to last way longer before needing repairs, which means fewer headaches and repair bills down the road. Their precision and tough construction keep everything running like clockwork, so no wonder manufacturers across the board consider them essential equipment for any serious production floor setup.

Smart Thickness Control (0.8-3.0mm Capacity)

Smart thickness control features let operators make accurate adjustments when working with different material thicknesses anywhere between 0.8mm all the way up to 3mm thick. The flexibility of these machines means they can handle various applications and work with many different types of materials, which naturally opens up new markets for businesses. Metal roof manufacturing equipment with this kind of adaptability helps producers meet all sorts of customer needs while cutting down on wasted materials. Some factories report around a 20% reduction in scrap after implementing these smart controls. When manufacturers install these intelligent systems, they improve their production workflow and save money at the same time because there's simply less waste going into landfills. These savings help bottom lines stay healthy while doing something good for the planet too.

Hydraulic Cutting Technology

Hydraulic cutting tech makes all the difference when it comes to getting those clean, accurate cuts needed for quality purlins that fit right with everything else in construction projects. What's great about this method is that it delivers better accuracy while making the whole manufacturing process safer for workers. According to some research out there, these hydraulic systems actually cut down on cutting time by around 25 percent, which means faster production overall. Anyone looking at equipment such as standing seam metal roof machines should seriously consider what hydraulic technology brings to the table. The combination of precision work and efficient operation really helps manufacturers crank out products faster without sacrificing quality standards across different applications in the building industry.

Advantages Over Conventional Steel Framing Methods

25% Energy Savings vs Traditional Tile Machinery

Purlin roll forming machines tend to save a lot of power compared to older tile making equipment, sometimes cutting energy use by around 25%. For factory owners looking at the bottom line, this means real savings over time while also being better for the planet. Less electricity usage fits right into what most companies are trying to achieve nowadays with their green initiatives, which helps cut down on those pesky carbon emissions everyone talks about. Energy audits have actually shown pretty impressive drops in CO2 output when switching to these newer systems, making them increasingly popular among manufacturers who care about both profits and planet health.

Quick-Change System for 12+ Profile Designs

Modern purlin roll forming machines come equipped with quick change systems that let manufacturers swap out over twelve different profile designs without much lost time during transitions. What really matters here is how this flexibility transforms day-to-day operations for businesses needing to respond fast to what customers want or new developments happening across industries. When companies offer such a wide range of products, they naturally attract more varied clients who need specialized solutions for their particular applications. Industry data shows something interesting too companies that make good use of these rapid switching capabilities often report around 30% higher monthly outputs compared to those stuck with traditional setups. So while it might seem like just another technical upgrade at first glance, the real impact comes from being able to keep pace with ever changing market demands while maintaining high levels of productivity throughout.

The adaptability and efficiency offered by these advanced machines make them an invaluable asset for companies looking to stay competitive and efficient in the ever-evolving construction market.

Selecting Equipment for Standing Seam Roof Production

Key Considerations for Metal Roof Machine Purchases

There are a few important things to think about when looking at machines for standing seam roof production. Efficiency should definitely be near the top of the list, covering both how much the machine can produce and whether it works well with different types of materials. Getting a machine that fits nicely with what's already in place makes all the difference in day-to-day operations, streamlining the whole process without hiccups. Cost matters too, obviously. A good look at what something will cost over time helps with budgeting decisions down the road. Industry standards and what other people say about different brands can give valuable information about who makes quality equipment and what kind of money back someone might expect after making an investment. These points together form a pretty solid foundation for anyone shopping around for a standing seam roofing machine.

CE-Certified Safety Features

When dealing with metal roof machines, safety comes first, which is why CE certification matters so much. Machines with this certification have met basic safety requirements across the industry. Look at what makes them safe emergency stops, protective guards, and various sensors all help prevent accidents while the machine runs. These safety features really count. Some studies show workplaces using safer equipment experience around a third fewer incidents. Beyond keeping workers safe, better safety means less time lost due to accidents and fewer legal headaches. For anyone shopping for a metal roof manufacturing system, machines built with strong safety protocols just make more sense in the long run.