Key Features of Modern Shutter Door Machines

Robust Security Mechanisms for Industrial Applications

Security is really important for industrial operations since unauthorized access happens all the time. These days, most shutter door systems come equipped with various security features meant to boost protection against break-ins. Things like heavy duty locks and designs that resist tampering make a big difference in keeping intruders out. Factories that don't invest properly in door security tend to get into trouble more often. The numbers back this up too many plants without good shutter door security report some kind of theft or unauthorized entry every year around 40% according to recent data. Putting in place better shutter door technology definitely cuts down on these problems, which means businesses protect their expensive equipment and confidential information much better than before.

Aesthetic Integration in Door System Designs

Security remains important, but today's shutter doors go way beyond basic protection. Many manufacturers actually design them to match building architecture these days. They provide all sorts of color choices, different materials from steel to aluminum, and various styles so businesses can pick what fits their look best. Take retail stores for example – we're seeing more shops incorporate branded elements into their shutters. Luxury car showrooms stand out here. Some high end dealerships have their company colors built right into the shutters themselves. This approach works really well because it keeps things secure while still making a statement about the brand. What used to be purely functional equipment is now something that contributes positively to storefront appearance without compromising on safety aspects at all.

Precision Control Systems for Smooth Operation

Control systems for precision are really important when it comes to keeping shutter doors running smoothly. Take a look around most industrial facilities and commercial buildings today, and what do we see? Systems that incorporate the latest tech developments, making those heavy doors open and close just right every time. We've seen some cool new stuff lately too - things like digital interfaces and smart sensors that actually respond faster and hit their marks better than older models did. Industry insiders know that getting this kind of precision right makes all the difference for door systems in general. Less breakdowns mean fewer repair calls and lower costs over time. When companies invest in these optimized mechanisms, they get reliable performance day after day without needing someone standing there constantly adjusting things by hand.

Energy-Efficient Motors and Automation

Putting energy efficient motors into shutter door systems can really cut down on running costs without sacrificing how well they work. These motors just don't guzzle electricity like older models did, so facilities actually see big savings month after month. When paired with automation tech, things get even better. Automated systems handle door movements smoothly, cutting wait times and preventing unnecessary wear and tear. Warehouse managers tell us they've seen real results too. One distribution center saved around 30% on their monthly energy bill after upgrading both motor type and adding smart controls. Makes sense when you think about it these days with energy prices going through the roof. The combo of efficient hardware plus smart automation isn't just good for the bottom line it's becoming standard practice across many manufacturing sectors looking to stay competitive while keeping environmental impact low.

Galvanized Steel vs. Aluminum Composite Options

Selecting the right material for shutter doors really comes down to picking between galvanized steel and aluminum composites. Steel stands out because it's super tough and strong, which makes it great for places like factories or secure facilities where the door needs to hold up under pressure literally. The zinc layer helps prevent rust and keeps things looking good longer, though there's a catch – steel weighs a lot more than alternatives. This extra weight can drive up transportation expenses and make installation trickier for some contractors. Aluminum composites tell a different story altogether. These materials are lighter on the wallet and eyes too, offering all sorts of design options without sacrificing much in terms of toughness. We see them popping up everywhere from home garages to office buildings where appearance matters just as much as function. Industry data shows both options work well for today's shutter door needs, but what works best usually depends on what exactly the customer wants and how deep their budget goes.

Powder-Coated Finishes for Corrosion Resistance

Powder coating really changes things when it comes to how long shutter doors last. Basically, what happens is they spray this dry powder on metal surfaces then bake it until it forms this tough, attractive layer. The end result? Shutters that stand up much better against rust, chips, and color loss. No more worrying about peeling paint or constant touch ups like we see with regular paints. Doors treated this way tend to stick around longer, so they're worth considering whether for business buildings or homes. Factory folks tell us their products show real gains too. Some tests even suggest these coated shutters resist corrosion about 30 percent better than ones without any coating at all. Makes sense why more people are switching over to this method for their exterior doors.

Adaptable Profiles for Commercial vs. Residential Use

Getting the right customization matters when it comes to serving different spaces, whether commercial or residential. Commercial shutter doors need extra tough construction and bigger sizes since they face constant wear from heavy foot traffic and must meet strict security standards. Residential options tend to focus more on looks and how easy they are to open and close day after day. Manufacturers adjust all sorts of characteristics to build shutter door models that really work for their specific purpose, balancing practicality with visual appeal. Take warehouses for example many companies now install automated systems on their commercial shutters so workers can get in and out quickly without fumbling with manual controls, especially helpful during busy periods when every second counts.

Climate-Specific Design Variations

The climate where someone lives plays a big role in how shutter doors are built and what they can do. Places that get really hot or really cold need good insulation so homes stay comfortable without wasting energy on heating or cooling. For folks living somewhere that rains a lot, water resistance becomes super important too. Many manufacturers have started including detailed charts showing which types work best for different climates. These charts often mention things like special paint jobs or sealants that help protect against rust and rot over time. When homeowners understand these differences between products, they end up picking options that actually stand up to whatever weather comes their way instead of just looking nice for a few months before falling apart.

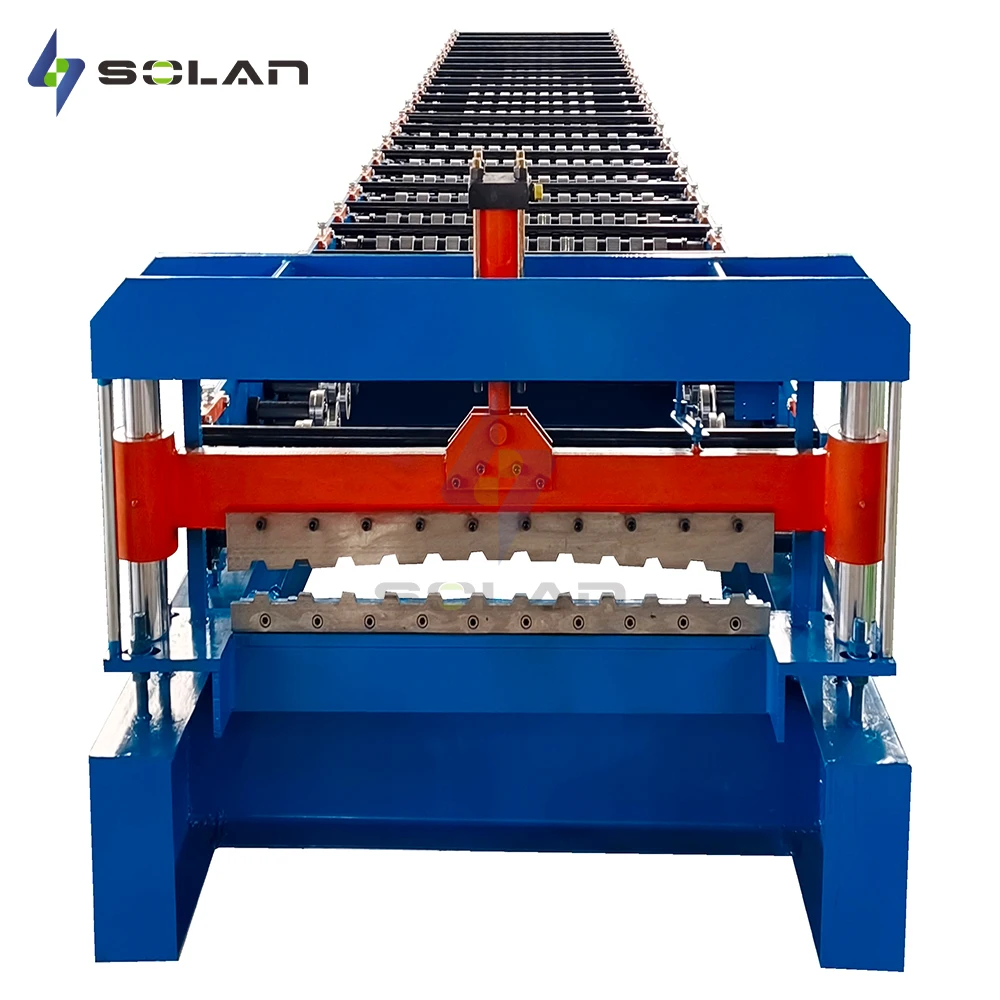

Full Automatic Shutter Door Frame Rolling Machine - Precision Manufacturing

Shutter door machines with automatic functions are changing the game in precision manufacturing thanks to some pretty impressive tech upgrades. These systems rely on highly accurate molds combined with rolling mechanisms that maintain consistent shapes across all products made. When manufacturers install automated controls, they cut down on manual labor requirements quite a bit, which means factories can run smoother and faster overall. Take automotive parts production as an example – once set up properly, these machines keep running nonstop through shifts without needing constant oversight. Many plants report seeing real gains after switching to automatic systems, with better quality control and fewer rejects coming off the line. As more shops make the move away from old school methods, it's clear these modern solutions offer substantial advantages when it comes to both accuracy and volume production capabilities.

High-Quality Multi-Material Forming System

Multi Material Shutter Machines bring something special to the table for door manufacturers. They work well with all sorts of materials including aluminum, stainless steel, and others that customers want these days. The market keeps asking for doors made from multiple materials, so being able to switch between them gives manufacturers a real edge. When shops adopt these machines, they find themselves able to take on projects with different design requirements without switching equipment constantly. Factories report faster production times when they don't need to stop and change tools mid project. Real world experience shows that shops with this kind of equipment tend to win more contracts because they can deliver exactly what architects specify. In an industry where orders keep changing week to week, having machines that adapt quickly means the difference between staying competitive and falling behind.

Australia-Specific Climate-Adaptive Roll Former

The tough Australian climate requires equipment built for the job, which is exactly what Adaptive Roll Formers deliver through their specially designed models. These machines come with features such as rust proof coatings and powerful drive systems that stand up against extreme weather conditions found across different parts of the country. Putting these innovations into practice means better performance over time and longer lasting equipment, no matter how rough the environment gets. Real world tests show these machines hold up well across various settings, whether it's for basic home security installations or complex requirements at large industrial sites. What makes them work so well down under is this balance between ease of operation and sheer toughness needed to handle our unpredictable weather patterns.

Low-Maintenance Indian Construction Model

The Indian market has seen growing interest in machinery that requires little upkeep and works reliably day after day. That's exactly what Indian Shutter Machines deliver. What makes these models stand out? They come equipped with things like self lubricating bearings and intelligent control systems that cut down on regular maintenance tasks and save money over time. Many factories across India have already switched to these machines, reporting noticeable boosts in production rates without breaking the bank. The solid build quality means these shutters last longer than most competitors, which explains why so many small business owners keep coming back for more units despite the initial investment.

Maintenance Strategies for Long-Term Performance

Self-Lubricating Component Systems

Shutter door systems with self-lubricating parts cut down on how often they need maintenance because there's no longer any need for someone to manually apply lubricant all the time. The materials used in these systems actually spread the lubricant around as they work, which keeps everything running smoothly and means less wear and tear over time. We've seen some pretty good improvements lately in how these lubrication systems function, so now we're seeing much less downtime when it comes to maintenance issues. Industry numbers suggest that doors with this self lube feature tend to be about 30 percent more reliable than traditional ones. That makes sense for businesses looking to get more years out of their equipment without having to spend so much time and money keeping things oiled and working properly.

Modular Repair for Minimal Downtime

Modular repair systems really boost how well operations run because they let people swap out parts fast and simple. With this modular approach, workers can take out just what needs fixing instead of tearing everything apart for a full system overhaul, which cuts down on downtime quite a bit. Manufacturing plants and warehouses across the country have jumped on board with these modular setups. Some companies report cutting repair time nearly in half while saving money at the same time. These systems make repairs go smoother overall, so business doesn't grind to a halt when something breaks down. For shutter door maintenance specifically, having modular options means technicians spend less time troubleshooting and more time getting things back online quickly after issues arise.