Doveďte svou výrobu střešních tašek na novou úroveň s naší válcovací stroj pro lemování tašek nové generace. Rychlejší tváření, ostřejší reliéfy a chytřejší automatizace – ideální pro lemované tašky z PPGI, PPGL a hliníku.

Hlavní sekce

Válcovací stroj pro kvalitní lemované tašky

Vysokorychlostní · Vysokopřesný · Vysoce efektivní

Podle místní ukázky dokáže zařízení dosáhnout maximální rychlosti tváření 8–12 m/min, což představuje zlepšení o přibližně 40 %–60 % ve srovnání s tradičními modely.

Optimalizací převodového poměru převodovky, výměnou servozásobovacího systému a použitím nově navržené formy pro reliéf je povrchová struktura kovových lemovaných tašek více trojrozměrná a hrany jsou tvarovány hladčeji.

Proč si vybrat náš glazovaný taškový profilovací stroj?

1. Rychlejší výroba, vyšší výkon

Náš nový design zvyšuje rychlost výroby na 8–12 metrů/min, což výrobcům umožňuje zpracovávat velké objednávky a zkrátit dodací dobu.

2. Skutečný 3D efekt tašek

Pokročilé reliéfní válečky vytvářejí ostré, keramické vzory tašek s bohatými křivkami a vysokou povrchovou definicí – ideální pro luxusní střešní projekty.

3. Stabilní a přesné tváření

Hladké přechody vln

Konzistentní délky tašek

Dokonalé překrytí tašek

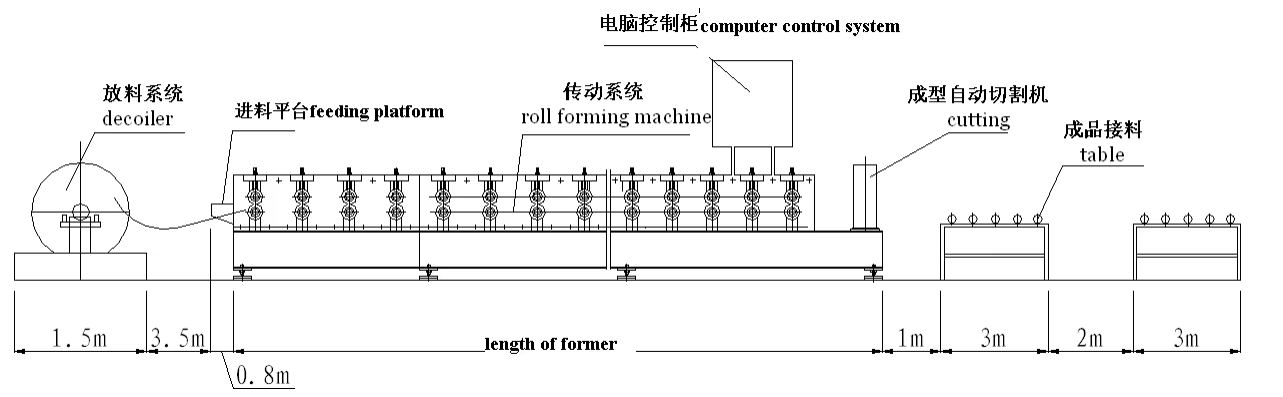

4. Chytrý automatický systém

PLC + dotyková obrazovka

Automatické počítání a řezání

Výstražný systém poruch a diagnostika chyb

Vzdálená technická podpora

Snížení závislosti na obsluze a zlepšení stability výroby.

5. Energeticky úsporný design

Optimalizovaný převodový systém a vylepšená hydraulická jednotka snižují spotřebu energie o 18 % ve srovnání se staršími modely.

Použití

✔ Střešní krytiny pro rodinné domy

✔ Lehká ocelová konstrukce

✔ Průmyslové stavby

✔ Střešní krytiny pro skladové haly

✔ Prefabrikované domy

✔ Projekty exportních střešních tašek

Technické specifikace

To výrobně