✔ User-Friendly Operation – Simple controls for hassle-free tile making machine use

✔ Energy Efficient Design – Reduces power consumption while maintaining high output

✔ Multi-Material Compatibility – Works with aluminum, steel, and galvanized iron sheets

✔ High-Speed Production – Optimized for fast roofing sheet making machine performance

✔ Durable Construction – Heavy-duty frame ensures long-term reliability

✔ Customizable Profiles – Adjustable for different corrugated tile designs

✔ Low Maintenance – Designed for easy upkeep in sheet metal machine applications

Roofing Industry – Produces corrugated steel & aluminum roofing sheets

Construction Sector – Ideal for wall cladding and roofing in building projects

Small & Medium Businesses – Perfect machine for small business metal fabrication

Industrial Manufacturing – Supports high-volume tiles machi production

Upgrade your production with Suolan’s Corrugated Tile Making Machine – the smart choice for efficient, high-quality metal sheet forming!

1 |

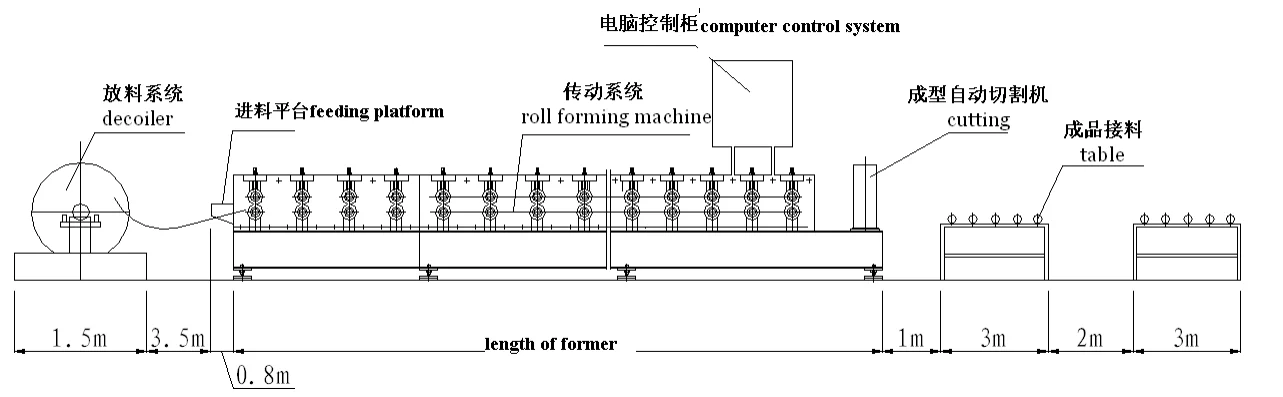

Driven system |

It is driven by an A.C. motor through a gear reduction drive train. |

||||

2 |

Pinch rollers |

It is driven by a chain&sprocket drive arrangement through both the corrugation rollers |

||||

3 |

Feed platform |

With gauge blocks to adjust the sheet width; it can slides according to actual need. It is adjust by crank. |

||||

4 |

Tensiometer arrangement |

It is fixed on the housing to tighten the chains. Please see photos as below. |

||||

5 |

Exit table |

It is set to receiving and supporting the corrugation sheets. |

||||

1 |

Power supply |

380V, 50Hz, 3 phrases or at buyer’s requirement |

||||

2 |

Material |

thin galvanized sheets |

||||

3 |

Productivity |

30--36 sheets from 0.14--0.20mm

15--18 sheets from 0.22--0.30mm

|

||||

4 |

Speed |

15--18 strokes/min(can be adjusted by pulley) |

||||

5 |

Barrel Length |

3600 MM |

||||

6 |

Diameter Of pinch rolls |

340mm*2 pieces |

||||

7 |

Diameter Of corrugation rolls |

380mm*2 pieces |

||||

8 |

Material thickness |

0.3mm --0.8mm |

||||

9 |

Formed width |

custom made |

||||

10 |

Power |

6kw |

||||

11 |

Feeding width |

1000mm |

||||