How Automated Roll Forming Machines Enhance Production Efficiency

Reduced Labor Costs Through Full Automation

Bringing automated roll forming machines into manufacturing really takes the pressure off manual labor forces, often saving businesses around 30% on labor costs alone. When factories automate those boring, repetitive jobs that used to tie up workers all day, they free people up for actually important work that requires thinking instead of just muscle power. Companies start seeing better productivity across the board because employees aren't stuck doing mind numbing tasks anymore. Plus, when we talk about robots and pre set machines taking over production lines, there's another big plus nobody mentions much these days. These systems make fewer mistakes than humans do, which means products come out looking exactly the same every single time. Less rework required translates directly into money saved while customers get consistently good quality products they can trust.

High-Speed Output for Scalable Production

Roll forming machines automate at impressive speeds, often going over 100 feet per minute, which makes them perfect for when companies need to crank out large quantities fast. Manufacturers love these machines because they can easily scale up or down depending on what the market wants at any given moment. The real benefit comes from running so quickly it basically doubles production while smoothing out all those little bottlenecks that slow things down in traditional factories. For businesses competing against others trying to get products to shelves first, having this kind of flexibility means the difference between winning contracts and watching competitors take market share.

Precision Engineering and Material Optimization

Minimized Waste with CNC-Guided Accuracy

CNC guided machines used in roll forming cut down on wasted materials quite a bit, around 20% according to industry reports. These machines have really precise cutting abilities that make sure almost every part gets used properly during production runs. When there's less scrap left over after manufacturing, companies save money on raw materials while their supply chains run smoother too. Factories adopting this tech tend to see better results across the board. Metal roofing manufacturers especially benefit from these improvements since they work with long sheets of material where even small reductions in waste add up fast over time.

Standing Seam Technology for Reduced Rework

Standing seam tech has really transformed how things get made, offering solid protection against weather damage while cutting down on those annoying fixes later on. These systems stop water from getting inside and make buildings less prone to structural problems over time. The savings add up too when looking at maintenance costs down the road. Construction companies especially rely on this stuff because their products just can't afford any flaws. Take roofing for instance - the machines that create standing seams are absolutely essential for keeping rain out and making sure buildings stay strong through all sorts of conditions. Factories that switch to these systems see fewer mistakes during production runs, which means faster turnaround times and less wasted materials overall.

Energy Efficiency and Operational Cost Savings

Hydraulic vs. Traditional Power Consumption

Switching to hydraulic systems for roll forming machines cuts down on energy usage quite a bit when compared to old school mechanical setups. Some tests show these hydraulic systems actually consume around 40 percent less power than their mechanical counterparts. What this means is businesses save money month after month as they watch those utility bills shrink. For manufacturers looking at long term savings, investing in hydraulics pays off pretty quickly because of all those ongoing cost reductions. Plus, factories running on hydraulic power tend to run smoother and last longer too, giving them an edge over competitors still stuck with outdated equipment.

PLC Systems for Predictive Maintenance

Roll forming machines get a major boost in how they work when equipped with Programmable Logic Controllers (PLCs). These controllers keep an eye on machine performance and actually predict when maintenance might be needed before problems happen. The result? Some companies report cutting down on downtime by around 20-25%, which means production keeps moving without those frustrating stoppages. When businesses install PLC systems, they're basically getting ahead of possible breakdowns. Machines last longer this way, and there's less money spent fixing things or replacing parts all the time. For manufacturers dealing with tight budgets, this makes a big difference. Less downtime plus extended equipment life translates to real cost savings over time, not to mention better overall productivity across the shop floor.

Top Automated Roll Forming Machines Cutting Costs by 40%

Full Automatic Double Layer Corrugated Roof IBR Trapezoidal Machine

The Full Automatic Double Layer Corrugated Roof IBR Trapezoidal Machine represents a major step forward in roll forming tech. With its built-in automation and special design elements, this machine produces tough, budget-friendly double layer roofing materials that stand up to harsh conditions. What really sets it apart is how fast it can run through an entire production cycle without needing constant manual intervention. Factories using this equipment typically see their bottom line improve because they spend less on both labor hours and overall manufacturing expenses. Many manufacturers who switched from traditional methods report cutting their operating costs somewhere around 35-40%, which explains why so many construction companies are investing in these machines to keep pace with modern demands for faster, cheaper roofing solutions.

High-Speed Drywall Metal Stud C/U/W Making Machine

Designed specifically for builders and contractors, the High-Speed Drywall Metal Stud C/U/W Making Machine delivers fast production speeds with exceptional accuracy when creating metal studs. What makes this machine stand out is its easy-to-switch tooling system that cuts down on those frustrating setup periods between jobs, which means workers spend less time adjusting and more time actually producing. Real world feedback shows operators typically see around a third boost in their daily output numbers, plus they save money on staffing because fewer people are needed to run the line compared to traditional methods. Many shops report being able to take on bigger projects within their existing workforce capacity after switching to this type of equipment.

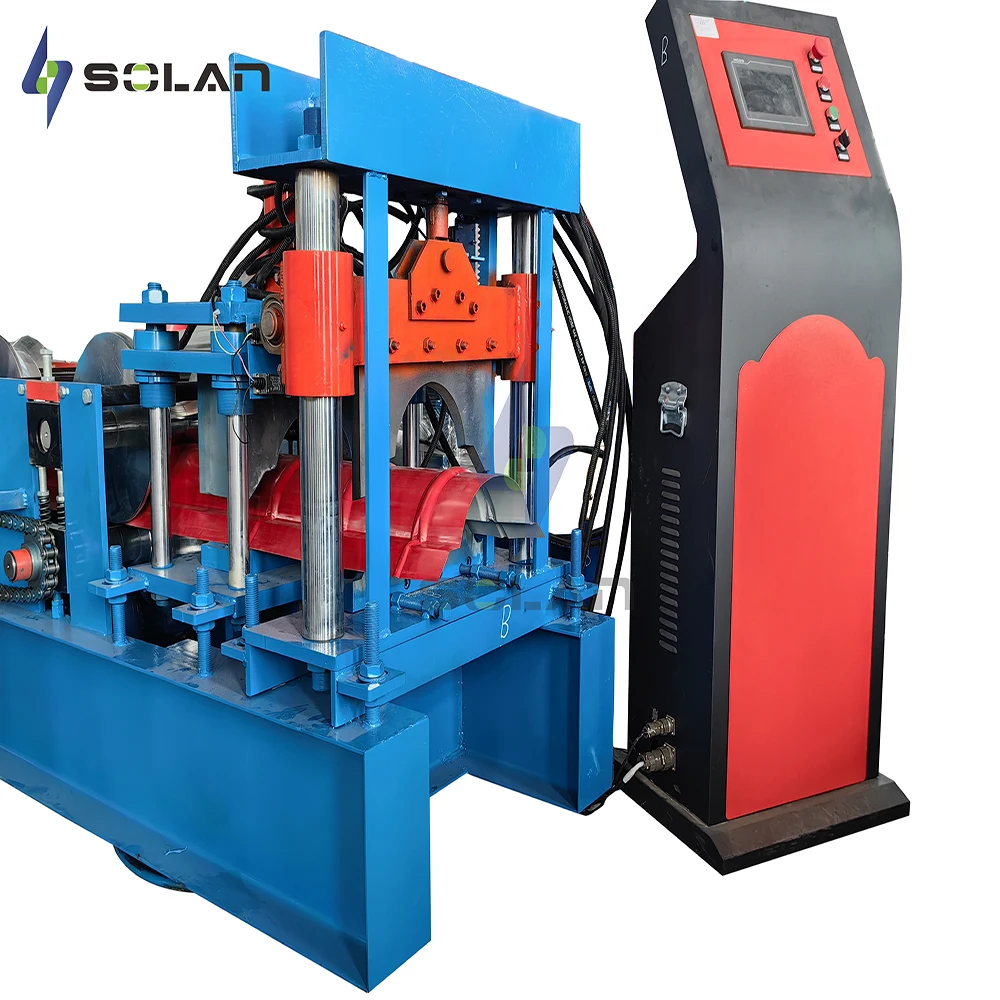

Customized Stud & Track Roll Former with PLC System

A customized stud and track roll former equipped with a PLC system gives manufacturers flexibility since different setups work better for various production requirements. When we install these PLC systems, they help keep everything running consistently while cutting down on those annoying product defects that waste time and materials. What makes this equipment really valuable is how it can be tailored exactly to what clients need, which means companies aren't stuck using one size fits all solutions anymore. For shops trying to compete in today's market, having machines that adapt to their particular workflow instead of forcing them into standard processes makes a huge difference in quality control and overall efficiency.

Floor Ceramic Tile Decking Roof Sheet Machine

Specialized in manufacturing roofing sheets, the Floor Ceramic Tile Decking Roof Sheet Machine blends efficiency with quality to ensure durability. It adheres to industry standards, minimizing defects and returns. Through minimizing rework and reducing material waste, companies benefit from a noticeable decrease in overall costs.

Electric Hydraulic Round Ridge Cap Roll Former

The Electric Hydraulic Round Ridge Cap Roll Former is built specifically for making ridge caps efficiently. It combines electric and hydraulic components to cut down on power usage during operation. For businesses looking to save money on their utility bills, this equipment represents a greener alternative without sacrificing performance. The machine's small footprint makes it adaptable to different shop floor arrangements, which means manufacturers can tweak their setup as needed without major overhauls. This kind of adaptability translates into better workflow management across various production environments.