Benefits of Modern Metal Roof Fabrication Equipment

Enhanced Durability Through Precision Engineering

Today's metal roof fabrication gear comes with some seriously advanced engineering that makes metal roofs last much longer than before, often between 30 to 50 years in many cases. The latest machines incorporate cutting edge materials and protective coatings such as Kynar 500, giving them serious staying power against rust and whatever Mother Nature throws at them. Because these roofs hold up so well over time, there's just not as much need for fixing leaks or replacing sections down the road. When manufacturers invest in this kind of precision equipment, they find their maintenance routines get simpler too. Less time spent on upkeep means better performance stays consistent while saving money in the long run. For big construction projects where budgets matter a lot, this kind of durability translates into real savings that make all the upfront costs worthwhile.

Energy Efficiency in Roof Panel Production

New developments in metal roofing equipment have made significant strides in reducing energy consumption, with some models using around 30 percent less electricity during manufacturing. These modern machines work with recycled materials and streamline production methods so they leave a smaller environmental mark, something that fits right into current worldwide efforts for greener manufacturing. Research shows buildings equipped with these efficient systems often see about a 20% drop in heating and cooling costs too. So from both an ecological standpoint and wallet perspective, going green with metal roofs actually pays off in the long run. That's why more manufacturers are jumping on board with sustainable practices these days.

Multi-Profile Flexibility for Complex Projects

Today's roll forming machines offer something special for metal roofing work because they can handle so many different profiles. Contractors find these machines invaluable when dealing with unusual building designs or client requests for something customized. They produce those neat standing seam profiles that look great on buildings while also holding up well against weather conditions. Some real world examples show that using these machines cuts down on scrap metal by around 15% compared to traditional methods. That means saving money and being better for the environment at the same time. Architects especially appreciate this kind of equipment since it lets them realize complicated roof designs without having to sacrifice green building goals or blow the project budget.

Technological Innovations in Roll Forming Machinery

AI-Assisted Quality Control Systems

Quality control systems powered by artificial intelligence are making waves across sheet metal fabrication shops everywhere. These systems use machine learning to spot flaws as they happen during production, which helps maintain better quality standards overall. When running nonstop through the factory floor, they catch issues that even experienced workers sometimes overlook. Some recent studies show factories using this tech have seen around 40 percent fewer bad metal panels coming off their assembly lines. That means less time spent fixing mistakes and happier customers getting what they paid for without surprises. For companies working with roll forming machines specifically, bringing AI into the mix isn't just helpful it's becoming essential if they want to stay competitive while keeping costs under control.

Smart Thickness Adaptation Technology

Smart thickness adaptation tech represents a major leap forward for roll forming machines. These systems can tweak production settings on their own based on what kind of material they're working with. The real value comes from handling those inevitable differences in material thickness and composition without wasting so much scrap metal. According to folks who know the industry inside out, plants adopting this tech typically see around a 25% boost in how much they produce each day. That translates to real money saved and better product quality across the board. For manufacturing operations looking to stay competitive, implementing these adaptive systems means cleaner workflows where everything runs smoother and requires less hands-on monitoring throughout the process.

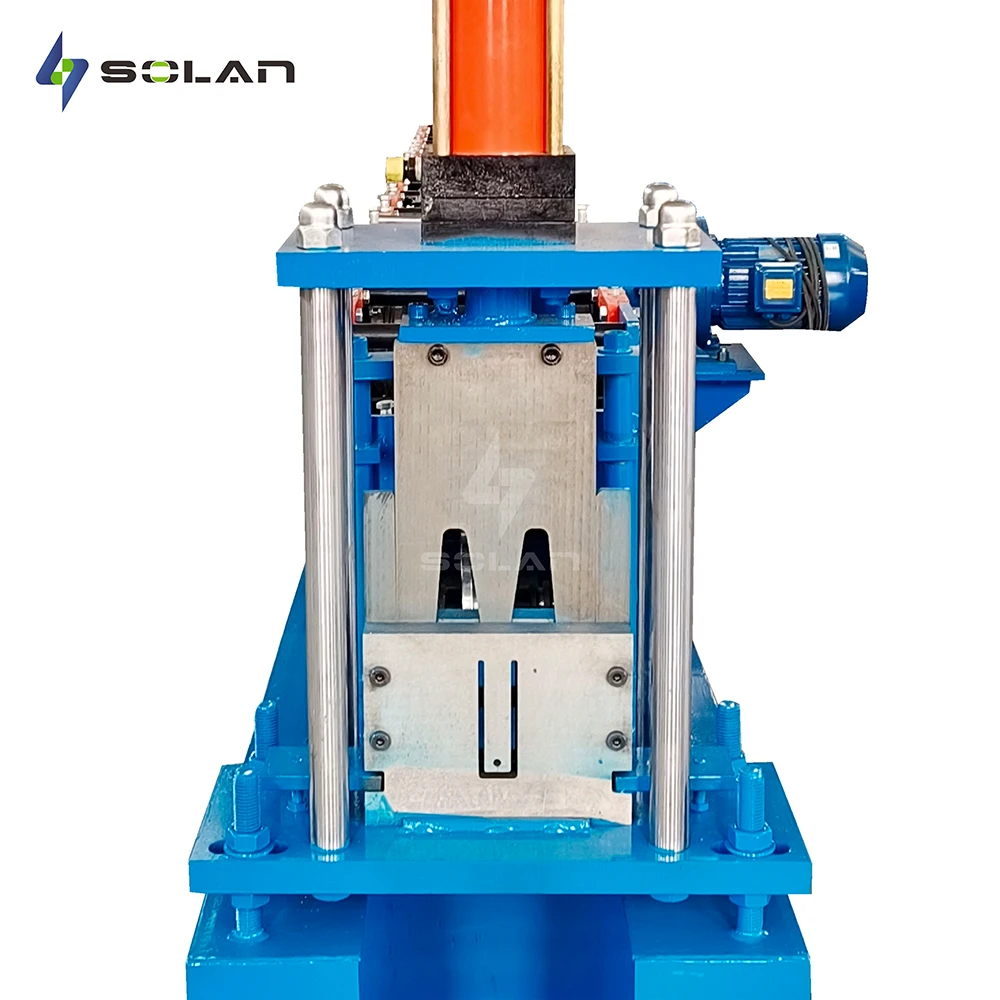

Hydraulic Cutting Advancements

Improvements in hydraulic cutting tech have made for much cleaner and more accurate cuts while putting less strain on materials during fabrication. Modern hydraulic systems can cut at speeds about 60% faster compared to older techniques. This speed boost means faster production times and better quality end products too. Less wasted material and reduced labor costs really show why investing in these systems makes good business sense. When looking at both cost savings and better material outcomes, it becomes clear why so many fabricators are switching to advanced hydraulic cutting for metal roofs. Looking ahead, manufacturers know that continuing to upgrade their hydraulic equipment will keep them competitive in producing top quality metal roofing solutions efficiently.

Advanced Roll Forming Machines for Modern Metal Roofing

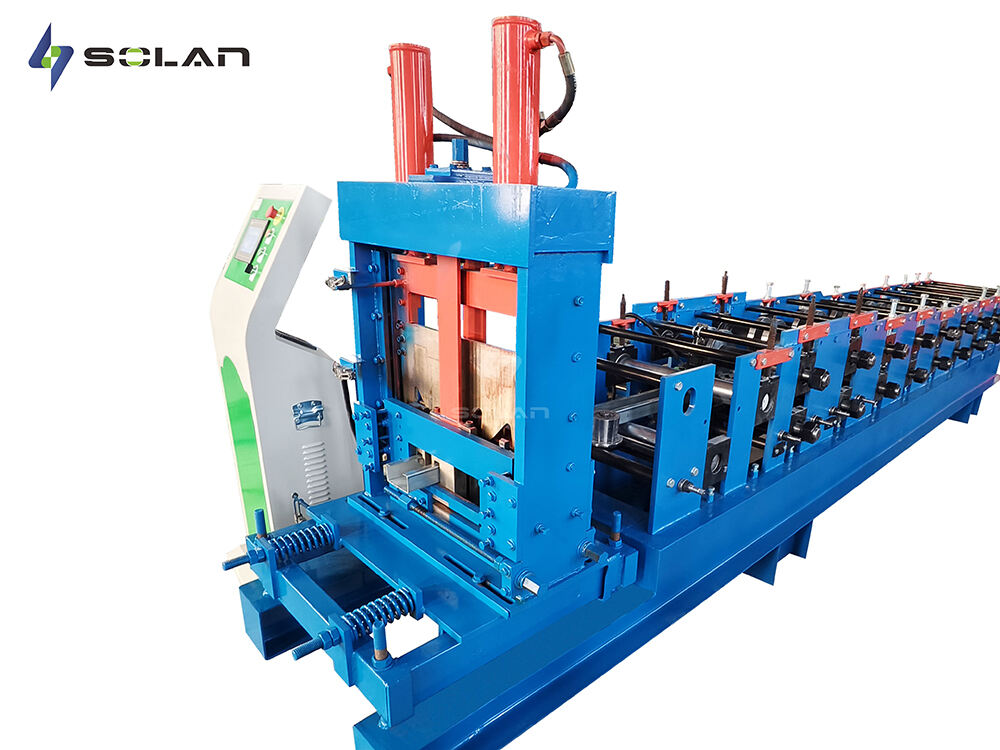

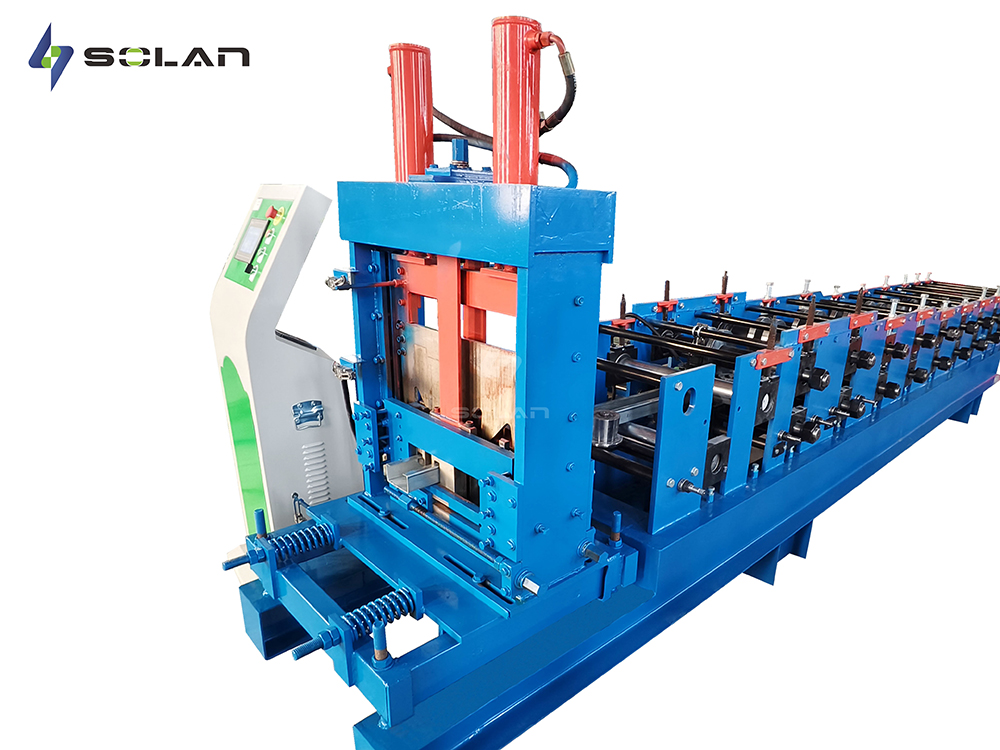

High-Speed C Channel Purlin Machine

The construction world moves at lightning speed these days, and machines like the High Speed C Channel Purlin Machine are changing how we get projects done faster. We're talking about production rates that go well beyond 25 meters per minute mark, which means crews can finish jobs quicker while spending less on manpower. What makes this equipment stand out isn't just speed though. The design actually incorporates some pretty smart flexibility options too. Workers can switch between different material types without much hassle. That kind of adaptability really opens doors for contractors working on everything from big factory buildings to shopping centers and even home additions where time matters most.

Deep U-Shaped Track Forming System

Deep U-Shaped Track Forming Systems are built tough for strength and stability, making them indispensable in heavy duty work. The design helps builders put together strong framework parts that meet all sorts of engineering specs. We've seen real world results from companies using these systems in both factory settings and big building projects. Structures last longer than expected, even when exposed to harsh conditions over time. These systems can handle U channels as deep as 400mm, something that really matters when getting solid structural integrity right from the start.

Climate-Adapted Shutter Door Machinery

Climate Adapted Shutter Door Machines work reliably even when weather conditions change constantly. The doors made by these systems provide good insulation and stand up to harsh weather situations, solving many problems caused by extreme climates. As buildings need to be more resilient these days, there's definitely a rise in demand for this type of machinery across the industry. These shutters do more than just keep out rain and wind they actually make both office spaces and homes stronger overall. Contractors are starting to see real value in investing in equipment that handles whatever Mother Nature throws at it.

Low-Maintenance India Market Solution

India's growing industrial landscape really needs solutions that require minimal upkeep if companies want their equipment to last longer and save money in the long run. When manufacturers design systems that don't need constant maintenance, the total cost of ownership drops dramatically. This means businesses can spend their budgets on other important things rather than constantly fixing broken machinery. These kinds of technologies work especially well in remote locations where getting service technicians isn't easy. That's why we're seeing more adoption across rural parts of the country. For the construction industry specifically, this approach helps support greener practices while still keeping operational costs under control.

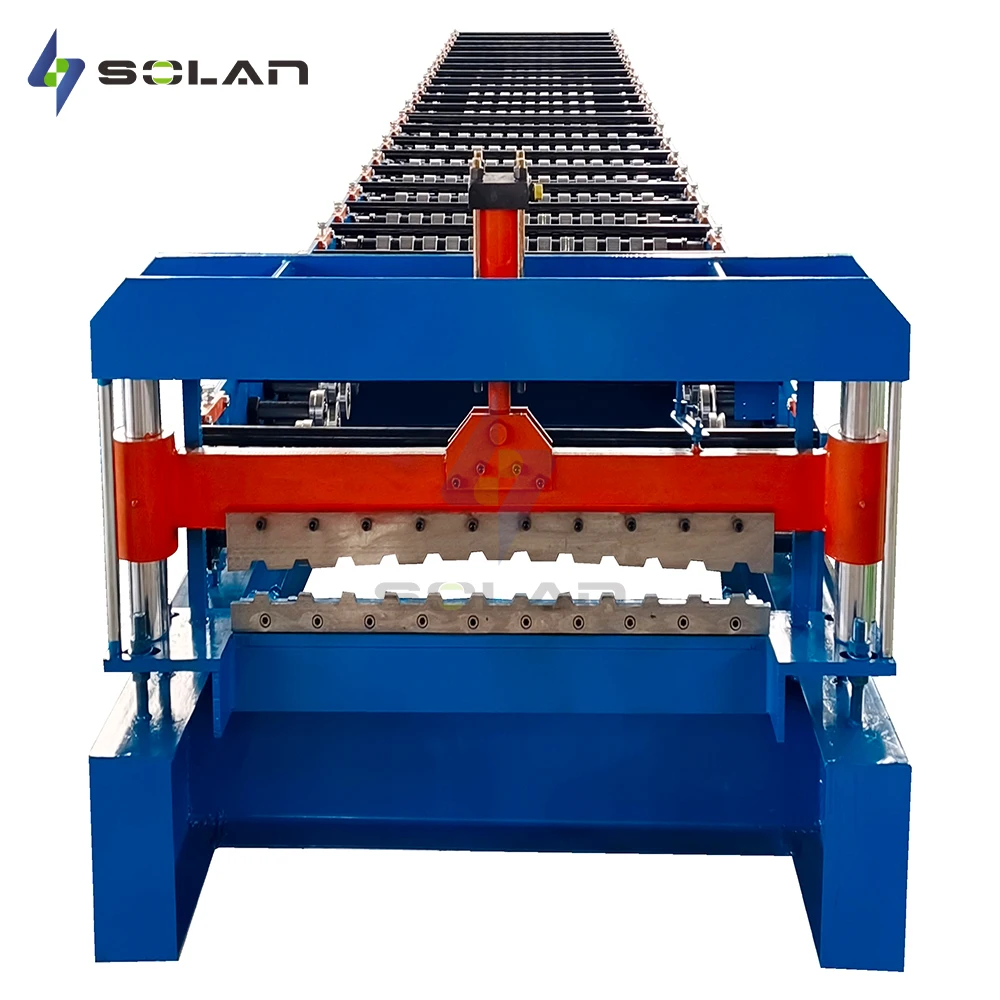

Omega Construction Multi-Function Unit

Omega Construction's Multi-Function Units stand out for their incredible flexibility, letting manufacturers churn out all sorts of metal profiles right from one machine setup. What really matters here is how these machines save floor space while cutting down on capital costs, plus they just plain work better on production lines than traditional setups. Industry insiders are already seeing signs that this kind of equipment might become standard issue in metal roofing shops over the next few years. Some early adopters report faster turnaround times and fewer changeovers between different profile types, which suggests we're looking at something that could reshape how metal fabrication works across the board.

In exploring these advanced roll forming machines, it is evident that technology continues to push boundaries, driving efficiency and versatility in metal roofing production. Whether it's a high-speed channel purlin machine or climate-adapted shutter door machinery, each unit here contributes uniquely to improving structural integrity and operational efficiency.

Selecting Optimal Metal Roof Making Equipment

Selecting appropriate metal roofing machinery requires a thorough look at what the specific job demands to avoid getting stuck with production holdups later on. When we get clear about what the project entails, we can better figure out how much capacity is needed, so the chosen machine actually works for the workload without constant adjustments. This approach also helps spot problems before they become major headaches down the line, preventing situations where machines just aren't matching up with what's required. Industry data shows picking the wrong equipment often adds around 25% extra time to completion schedules. That's why many shops now rely on some form of demand analysis when shopping for new gear these days. Looking at expected output levels and material flows makes all the difference in finding equipment that fits both current needs and future growth possibilities.

---

Looking at how different machines handle materials matters a lot when trying to run operations efficiently while keeping workers safe during production runs. Metal roof machines these days come with built-in systems that take care of loading and unloading materials automatically, cutting down on manual work requirements and minimizing chances for mistakes made by people. The upside here goes beyond just saving time money too. According to industry reports, companies that streamline their material handling methods often see around 20% drop in operating expenses over time. That kind of saving makes evaluating this aspect absolutely critical whenever choosing new machinery for shop floors.

---

Looking at how different machines consume energy is really important when manufacturers want to pick equipment with good efficiency ratings. When companies run life cycle assessments on potential purchases, they find out which machines actually save money over time instead of just looking at upfront costs. Getting better at using energy helps cut down on bills while still hitting those green targets most businesses have these days. Some real numbers back this up too many factories report spending around 30% extra on operations because they bought inefficient gear. So checking out energy consumption isn't just something nice to do it's basically part of smart business planning nowadays where companies need to worry about both bottom lines and carbon footprints at the same time.

Future Trends in Roof Forming Machine Technology

Integration of IoT in Roll Forming Processes

Bringing the Internet of Things into metal roofing production is changing how roll forming works, especially when it comes to equipment such as those standing seam metal roof machines we all know about. When these machines can talk to one another through IoT technology, they work together better than before, making the whole manufacturing process smarter day by day. The real value comes from having instant access to data and analysis tools that help predict when something might go wrong on the line. This means fewer unexpected stoppages and better overall performance from those metal roof fabrication systems. Industry insiders are betting big on this tech too. Most believe that by around 2030, most manufacturers will have adopted some form of IoT integration as part of regular business operations. This shift fits right in with what's happening across many industries where automation and decisions based on actual numbers rather than gut feelings are becoming the norm.

Sustainable Material Compatibility Expansions

More manufacturers are starting to focus on how well sustainable materials work with today's roll forming machines, which leads to greener results when using equipment such as metal roof machines available for purchase. Companies need to follow these trends if they want to comply with global sustainability rules and keep up with customers who increasingly ask for environmentally friendly buildings. According to some industry studies, going green doesn't just help businesses meet regulations it might actually boost their market position somewhere around 15 percent give or take. For instance, firms that have made the switch report better customer relationships and sometimes even lower long term costs. Metal roof forming machines from companies like New Tech Machinery stay competitive because they incorporate these eco practices into their design process right from the start.

Modular Design for On-Site Adaptability

The move toward modular designs in metal roof manufacturing equipment has become pretty much necessary when working at remote construction sites. Take the [metal roof making machine](#) for instance it comes with parts that workers can rearrange and tweak as needed, which saves money on shipping and setting things up. For jobs out in the boonies where regular machinery just doesn't make sense financially or logistically, this kind of flexibility makes all the difference. Some actual field reports show these modular setups can slash setup times by around 40 percent, meaning crews get started faster and finish sooner. Beyond saving cash on operations, these systems tackle those pesky logistics problems that plague so many construction projects across different terrains and conditions.