✔ 2025 Smart Automation - AI-assisted quality control system

✔ Deep U-Forming Capacity - Processes up to 400mm depth U channel profiles

✔ High-Speed Production - 25m/min output for industrial-scale operations

✔ Multi-Thickness Capability - Handles 1.5-6mm steel coils

✔ Precision Laser Guidance - ±0.15mm dimensional accuracy

✔ Energy Recovery System - 35% power reduction technology

✔ Quick-Change Tooling - Switch profiles in under 15 minutes

Steel Structure Construction - Essential purlin machine for prefab buildings

Warehouse Racking - Mass production of structural U channel tracks

Industrial Plants - Heavy-duty framing systems manufacturing

Infrastructure Projects - Bridge components and support structures

Technical Advantages:

• Military-grade servo motor system

• Integrated punching/notching unit (optional)

• Cloud-based production monitoring

Experience the Future of Steel Track Production!

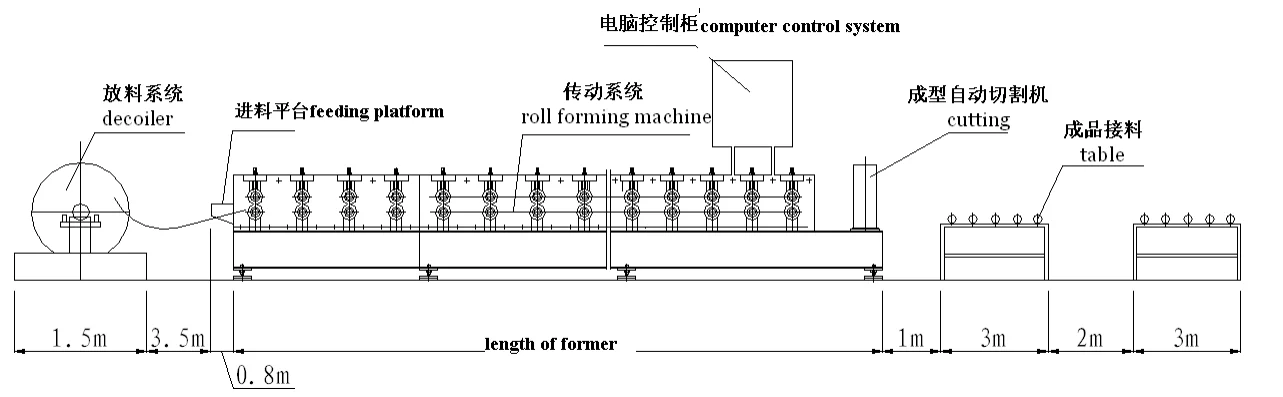

No |

Item |

Data |

1 |

Processing Material |

PPGI,GI,AL |

2 |

Formed Width(mm) |

As drawing |

3 |

Processing Thickness(mm) |

1-1.5 |

4 |

Material of Rollers |

45#steel,with hard chrome coated |

5 |

Diameter of Shaft |

80mm |

6 |

Production Speed |

0---15m/min |

7 |

Roller Driven |

Decelerating Motor+Chain Transmission |

8 |

Cutting Model |

Hydraulic Profile Cutting |

9 |

Length Measurement |

Encoder |

10 |

Control Style |

PLC control |

11 |

Total Power |

7kw |

12 |

Voltage |

380V 50HZ or at buyer's request |

13 |

Number of roller stations |

as designing |

14 |

Lead time |

30days |