✔ 2025 Upgraded Drive System - Premium gear & bearing assembly for vibration-free operation

✔ High-Torque Motor Core - 15% more power efficient than standard models

✔ Dual-Profile Capability - Switch effortlessly between IBR and trapezoid sheet production

✔ Smart Control Panel - Digital interface for precision thickness/speed adjustment

✔ Heavy-Duty Frame - Reinforced steel construction handles 0.2-0.8mm materials

✔ Auto Lubrication System - Extends roll forming machine component lifespan

✔ Energy Saving Mode - Reduces power consumption by up to 20%

Roofing Manufacturers - Mass production of colored steel roofing sheets

Prefab Construction - Ideal for construction machines in modular building projects

Metal Fabricators - Perfect machine for small business startups

Industrial Plants - High-volume tiles mach production up to 25m/min

Upgrade to the Future of Roof Sheet Production!

1 |

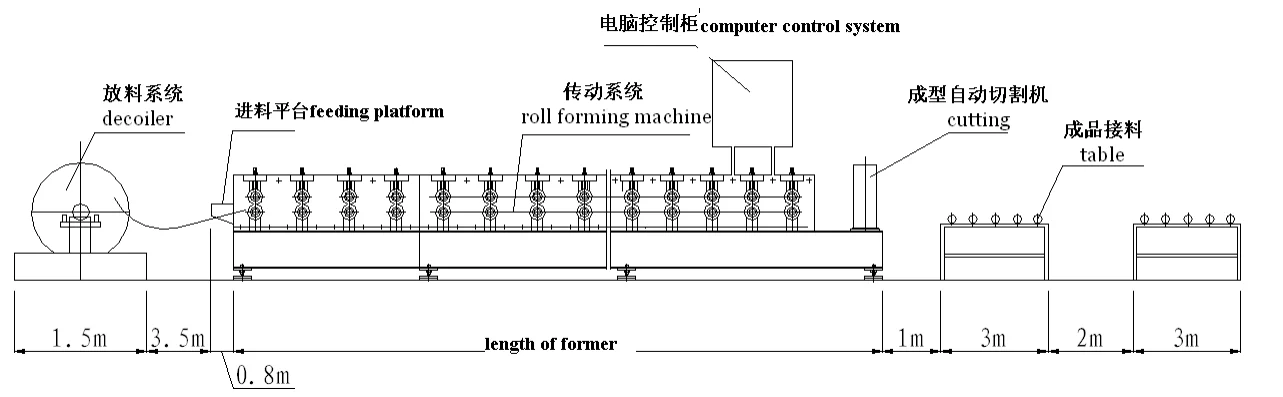

Decoiler |

It is used to support the steel coil and uncoil it in a turnable way. |

||||

2 |

Entry Beach |

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulatin to know the function of locate angle iron. |

||||

3 |

Main Roll Forming Machine |

Adopting welded sheet structure, motor reducer drive, chain transmission, roller surfaces polishing, hard plating , heat treatment and galvanizational treatment. |

||||

4 |

Shearing Mechanism |

Material of blades: Cr12 It contains one set of cutting tools, one hydraulic tank and one cutter machine. |

||||

5 |

Hydraulic Station |

It is controlled by gear wheel oil pump.The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes, and two sets of electromagnetism valves. |

||||

6 |

Computer Control Cabinet |

PLC Frequency Control System with touch screen |

||||

1 |

Processing Material |

PPGI,GI,Aluminium |

2 |

Processing Thickness(mm) |

0.3-0.8mm |

3 |

Material of Rollers |

45# steel,with heat treatment |

4 |

Diameter of Shaft |

Ф70mm |

5 |

Production Speed |

12---15m/min |

6 |

Cutting Model |

Hydraulic Profile Cutting |

7 |

Roller Driven |

Decelerating Motor+Chain Transmission |

8 |

Number of roller stations |

14 rows or as designing |

9 |

Voltage |

380V 50HZ or at buyer's request |

10 |

Total Power |

3+3 kw |

11 |

Operation Model |

Button + Touch Screen |