✔ Fully Automatic Operation – Minimizes manual labor with intelligent control systems.

✔ High-Quality Motor & Core Components – Ensures reliable performance and long service life.

✔ Multi-Functional Design – Produces IBR, trapezoid, and corrugated roofing sheets.

✔ Precision Roll Forming – Delivers consistent accuracy for forming machine applications.

✔ Adjustable Speed & Thickness – Customizable for different tile machine requirements.

✔ Robust Construction – Heavy-duty frame for stable rolling machine operations.

✔ Energy-Efficient Production – Low power consumption for cost-effective manufacturing.

Roofing Industry – Produces high-strength steel roofing sheets for commercial and residential buildings.

Construction Sector – Essential for construction machine setups requiring durable metal sheets.

Metal Fabrication Workshops – Ideal for making machine businesses in door making machine and roofing production.

Industrial Manufacturing – Suitable for production machines in large-scale sheet metal forming.

Upgrade your production line with Suolan’s Automatic IBR Trapezoid Roof Sheet Machine – the ultimate roll forming machine for high-quality tile making machinery!

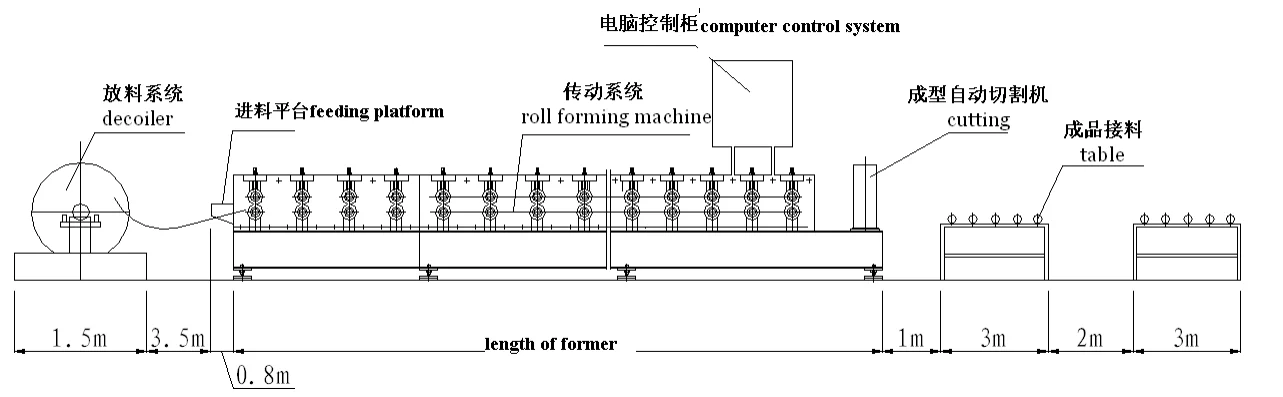

1 |

Decoiler |

It is used to support the steel coil and uncoil it in a turnable way. |

||||

2 |

Entry Beach |

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulatin to know the function of locate angle iron. |

||||

3 |

Main Roll Forming Machine |

Adopting welded sheet structure, motor reducer drive, chain transmission, roller surfaces polishing, hard plating , heat treatment and galvanizational treatment. |

||||

4 |

Shearing Mechanism |

Material of blades: Cr12 It contains one set of cutting tools, one hydraulic tank and one cutter machine. |

||||

5 |

Hydraulic Station |

It is controlled by gear wheel oil pump.The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes, and two sets of electromagnetism valves. |

||||

6 |

Computer Control Cabinet |

PLC Frequency Control System with touch screen |

||||

1 |

Processing Material |

PPGI,GI,Aluminium |

2 |

Processing Thickness(mm) |

0.3-0.8mm |

3 |

Material of Rollers |

45# steel,with heat treatment |

4 |

Diameter of Shaft |

Ф70mm |

5 |

Production Speed |

12---15m/min |

6 |

Cutting Model |

Hydraulic Profile Cutting |

7 |

Roller Driven |

Decelerating Motor+Chain Transmission |

8 |

Number of roller stations |

14 rows or as designing |

9 |

Voltage |

380V 50HZ or at buyer's request |

10 |

Total Power |

3+3 kw |

11 |

Operation Model |

Button + Touch Screen |