✔ High-Quality Material Compatibility – Works with color steel, galvanized metal, and aluminum sheets

✔ Precision Roll Forming – Produces consistent trapezoidal roof tiles with smooth edges

✔ Easy Installation & Operation – User-friendly design for quick setup and minimal training

✔ Energy-Efficient Performance – Low power consumption reduces operational costs

✔ Durable Construction – Heavy-duty frame ensures long-lasting sheet metal machine reliability

✔ Adjustable Speed & Thickness – Customizable for different roofing sheet making machine needs

✔ Low Maintenance Design – Simplified components for hassle-free upkeep

Roofing Industry – Manufactures glazed trapezoidal roofing sheets for residential & commercial buildings

Construction Sector – Ideal for wall panels and roofing in modern architecture

Small & Medium Enterprises – A cost-effective machine for small business metal fabrication

Industrial Production – Supports high-volume output for tiles mach manufacturing

Enhance your production efficiency with Suolan’s Trapezoidal Roof Tile Making Machine – the ultimate solution for premium-quality metal roofing sheets!

1 |

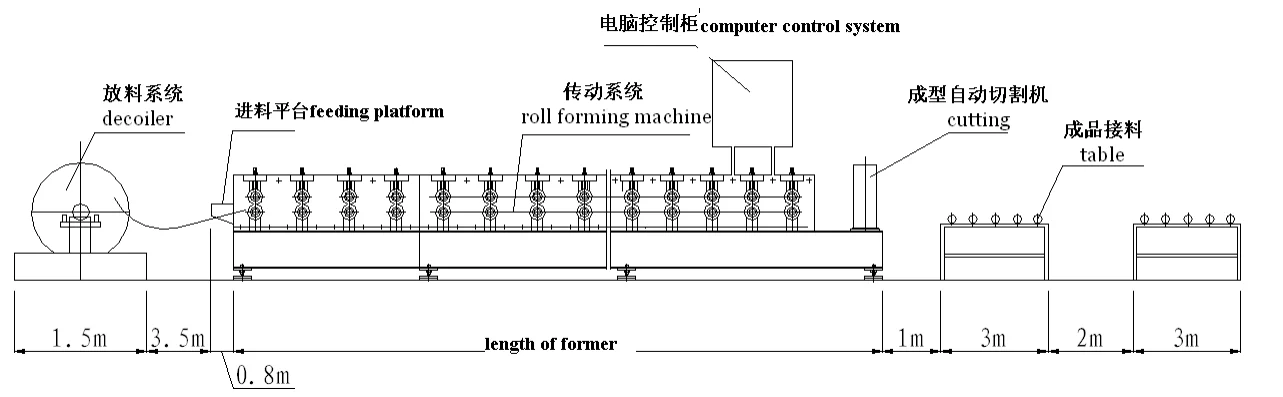

Driven system |

It is driven by an A.C. motor through a gear reduction drive train. |

||||

2 |

Pinch rollers |

It is driven by a chain&sprocket drive arrangement through both the corrugation rollers |

||||

3 |

Feed platform |

With gauge blocks to adjust the sheet width; it can slides according to actual need. It is adjust by crank. |

||||

4 |

Tensiometer arrangement |

It is fixed on the housing to tighten the chains. Please see photos as below. |

||||

5 |

Exit table |

It is set to receiving and supporting the corrugation sheets. |

||||

1 |

Power supply |

380V, 50Hz, or at buyer’s requirement |

||||

2 |

Material |

PPGI,GI,Aluminium |

||||

3 |

Productivity |

0-8m/min |

||||

4 |

Roller Driven |

Decelerating Motor+Chain Transmission |

||||

5 |

Input Width(mm) |

1000 or as designed |

||||

6 |

Diameter of Shaft |

Ф70mm |

||||

7 |

Cutting Model |

Hydraulic Profile Cutting |

||||

8 |

Material thickness |

0.3mm --0.8mm |

||||

9 |

Formed width |

custom made |

||||

10 |

Power |

6kw |

||||

11 |

Feeding width |

1220mm |

||||